In late March, ShopBot was fortunate enough to be invited to participate with the USFLN (US FabLab Network) booth at the ITEEA (International Technology and Engineering Education Association) Meeting in Orlando. The booth was staffed by Sallye Coyle (ShopBot), Caroline McEnnis (TIES), Andrea Lane (Lorain County Community College, Ohio) and David Richardson (LLCC, Ohio.)

It was a great opportunity for the educators and students to see some of the equipment available in a Fab Lab. In the photo below, you can see the vinyl cutter by Roland, which we used to cut copper strips for help in the electronics display. Caroline is demonstrating squishy circuits to a teacher. If you don’t know about squishy circuits, you are in a for a treat making conductive and resistant play dough to teach children and beginners about electronics in a safe and fun way.

While David handled a lot of the explanations of a FabLab, Andrea, whiz kid extraordinaire, oversaw the MakerBot and took over the ShopBots when I was otherwise occupied. It was great to have a 3D printer and ShopBots in the booth so that folks got a chance to see the difference between 3D printing_additive and 3D machining_subtractive. I confess that it was a difficult environment to successfully complete a build with the 3D printer, as accidental bumps, filament not feeding properly, whatever else goes on in the workings of a 3D printer would cause a build to stop in the middle of the run. The ShopBots just kept machining, and we sent folks to the MakerBot, Stratasys and 3D Systems booths to compare the brands of 3D printing equipment.

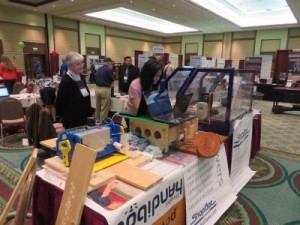

We had a Handibot with a jig for tiling and a Desktop ShopBot set up to engrave blanks at the booth. The Desktop was inside the optional enclosure that we usually ship with Desktops going to Europe…it has a magnetic switch that shuts down the Desktop if the lid is opened while machining. Educators seemed to think it a good idea if their students were aged middle school and younger, and more than was necessary for high school and older. In the photo above, note the wine rack, created by ShopBot’s TJ Christiansen, that has been repurposed as a table to raise the computers up to a reasonable height for standing and designing. We had VCarve Pro CAD/CAM software open on the computers running the ShopBots, and Aspire 3D CAD/CAM software open on the 3rd computer to show it to educators considering moving beyond V Carve Pro.

Students and teachers alike got into the CAD design and machining with the ShopBots. In fact, we ran past the official closing of the show, and they pulled the electricity before we finished running files designed for the Desktop by 3 teachers from Georgia. The nice thing about digital fabrication is that I could easily transfer the Design files to another layout and run them on the Handibot in my studio. So the teachers got their parts, and the added bonuses of videos of their work so they could show their students some of what they had been up to while attending the conference.

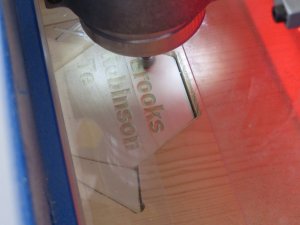

A neighbor dropped by while I was completing the projects for the teachers, and requested his own name plates for his dogs. (He claims the dogs belong to his wife, but I’ve seen how he takes care of them!!!)

In contrast to an ITEEA conference, a Maker Faire is open to the public to enjoy the creativity of those in the ‘Maker” movement.

April 12, the Bots participated in the Burlington (NC) miniMaker Faire. Set in the Holly Hills Mall and Business Center, the event was open to the public. 54 booths were set up throughout the mall, and the crowd seemed split between those who knew what was going on, and those who were just amazed because Steam Punk and 3D printing and laser cutting and electronics and— and— and— were out there for all to see. The traffic was steady, especially since the schools had a make-up day after all the snow and ice we have had this winter.

On the way in, I met Dan Porter, his CUBE 3D printer in hand, and asked him to share my table. In the “small world” category, Dan has used a ShopBot as an undergraduate in Fort Collins, Colorado. He made equipment for testing rats in the lab…and I used to test rats in the lab. Not only did I make a fantastic new friend, but again, we had the opportunity to show people that digital fabrication is not just 3D printing. In the photo below, Dan (in the white Building STEAM in Burlington T-Shirt) has just pulled his little 3D printed robot off his printer, and the little girl in her mom’s arms is watching the Handibot machine her name in a hexagonal blank. It did take over 20 minutes to make the robot, and about a minute to carve her name, but who’s counting.

I set up jigs so that we could drop the blanks into the jigs, then the folks could use the CAD software to design what they wanted to put onto the blank. Matt Wade, FabLab coordinator from Patrick Henry Community college in VA, played with Aspire loaded on the computer running the Desktop while Katie watched the Handibot in action (middle picture.)

Once the designs were toolpathed and the code written, the ShopBots would do their thing.

It didn’t matter if they were 3 years old or faculty looking to create a Maker Space, the fascination was there.

It might take a few minutes before someone decided they wanted to participate (notice girl with her parents peeking in behind Dan and friends)…but once they got started, they might make two (the same girl watching the second tile she designed machine on the Handibot.)

Thank you, Ben Harris, for inviting us to join the Burlington Mini Maker Faire.

Leave a Reply