Blog post written by Walter Dill

————————————

First, a little backstory about Walter Dill and Monica Uhl, aka DillUhlsional: Soon after our relationship began 7 years ago, Monica realized that together we are DillUhlsional, which is appropriate since we have hugely grandiose plans! 5 years ago, with significant support and editing from Monica and a few others, I had a successful Kickstarter campaign which helped acquire a ShopBot Desktop CNC router. The main project after fulfilling all 172 Kickstarter rewards has been customizing this 30’ 1956 Airfloat Land Yacht (Talulah) and outfitting our 1999 F450 7.3L diesel box truck (Clyde) to be our studio/gallery/woodshop/tow vehicle. Keep your eye out for future blogs about the various elements in both Talulah and Clyde that were made possible by the ShopBot Desktop.

The project that is featured in this blog post is the parquet floor or “truck floor de lis” for our mobile workshop

We were recently offered 2 boxes of very nice solid hardwood parquet flooring which had been acquired a few years ago at Habitat for Humanity. The unopened packages were stamped “Ernst Hardware” which had gone out of business 23 years ago. Note: Monica started learning CAD, VCarve, and running the ShopBot with this project.

There were nearly enough parquet panels to cover the 4’ x 12.5’ truck floor. A few panels resembled walnut. The others were lighter and looked more like a variety of mahogany. All had a very spicy smell – probably of Asian origins. We created a dark and light checkered perimeter using the squares of the dark wood alternating with a thick veneer birch plywood that was exactly the thickness of the parquet panels (1/4”). We chose to inlay a classic fleur de lis into the dark panels. The drawing below was used in VCarve Pro to make the inlays.

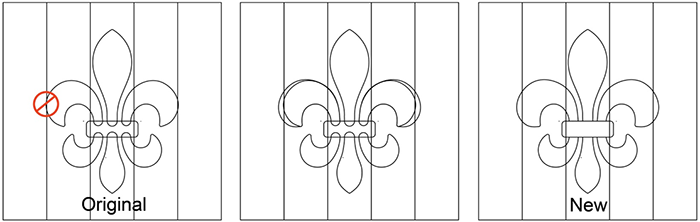

Drawing: Rhino3D CAD was used for all drawings. VCarve Pro is also capable of this type of drawing but doesn’t have the versatility of a full-blown CAD program. There are multitudes of fleur de lis variations on the internet. We adapted this version to fit the square format. The strategy was to make 6 separate parts for the “petals” (see drawing below) so the grain goes in the general direction of the petal.

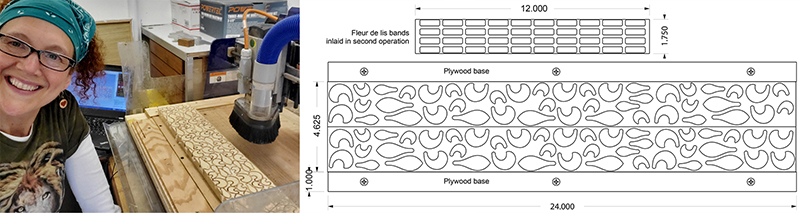

Hold down and begin routing: The individual panels had a paper backing and needed to be glued between the connected strips to make a solid board for routing. When glued up, there were subtle variances in dimensions and flatness. Therefore, we placed three at a time on the router table and kept them in groups of three and in the same order to ensure accuracy in the subsequent operations. Wedges secured the panels. The image (below right) is setting up for the second operation, to clean out and trim the outline with a 1/16” bit.

Redesign mid-stream/hindsight: After cutting all 45 inlay openings we realized that the larger petal needed to be a bit wider for aesthetic reasons (see drawing below). We placed the panels, in their sets of three, back in the router and trimmed the petals slightly larger.

Cut inlay parts: The 24” x 4 5/8” maple board was glued to a plywood base which extends to either side. (See drawing). This allows the workpiece to be screwed down to the spoil board with the screws being totally outside of the cutting envelope.

After routing, the parts were sliced off with the bandsaw using masking tape to hold the parts from falling into the blade. (Hint: if you haven’t already tried this, it’s a good trick.) The parts are then glued into the openings (below right) and clamped together (bottom).

Cut and inlay the “band”: The last inlay part cleans up the lines and is the finishing touch for the fleur de lis.

The glue-up: The completed parquet panels were first glued onto 1/8” plywood because the truck floor was not perfectly level. A 4’ x 8” sheet, about 2/3 of the floor, was prepped outside on a worktable using clamps and bricks for weights (below right).

Sanding, sanding, and more sanding: This is less than 2/3 of the final floor! The remainder was glued down in place. Then more sanding and sanding.

The finish: We have sealed the floor with Daly’s Ship and Shore to get the warm tones and will be applying Bona Traffic HD water-based whence the sealer is cured.

Now the ShopBot Desktop has a nice floor beneath its feet. See more pictures of the truck and trailer at https://www.dilluhlsional.com/airfloat.

_________________________________________

For questions or to get a free copy of the VCarve files for this fleur de lis contact: Walter Dill – walter@dilluhlsional.com and/or Monica Uhl – monica@dilluhlsional.com

Leave a Reply