By Sallye Coyle, November 7th, 2016 ATEA Region 5 meets in North Platte, Nebraska

North Platte, NE often serves as a stopping place on the transit between the East and the West Coasts of America. The Original Transcontinental Airways that carried mail between Washington D.C., New York & San Francisco made a stopover at the North Platte Landing Field, which was the first lighted airfield in the United States. Union Pacific Rail Road operates Bailey Field, the world’s largest classification yard, where railroad cars are sorted and sent out along the tracks in 23 states.

Display at the North Platte Landing Field It would be easy to drive right on through North Platte on Interstate 80 on your way across country. But if you do stop in North Platte, you will find a thriving community. Two Community Colleges serve many populations in North Platte, from teenagers working to finish their secondary education while getting college credit, to work force development in technology or health care, to continuing education classes in art, music or entrepreneurship. A large Union Pacific diesel engine graces the North Platte Community College North campus, and serves to train engineers and mechanics. That campus houses many applied technical programs such as building construction, HVAC, electrical, and automotive. Roger Fattig, who teaches building construction, ordered a ShopBot PRT alpha 4’ x 8’ a little over a year ago to introduce digital fabrication into the woodworking and building construction program. An article on their website describes how the ShopBot quickly and precisely cut the arches over the windows on the house that the building construction, HVAC, and electrical students built to auction off this year.

In October, North Platte Community College, a division of Mid-Plains Community College, hosted the Region 5 meeting of the American Technology Education Association (ATEA). The mission of the ATEA is to serve as the leading provider of professional development for postsecondary technical educators. Roger Fattig invited ShopBot to attend, and so I made the trip to America’s Heartland. It involved a flight to Denver, then a smaller prop plane to North Platte over golden landscape punctuated with green polka dots indicating irrigated crops.

Center-pivot irrigation, or water wheels, allow farmers to grow crops. North Platte is a friendly place. I chose to eat dinner at the airport diner, and was perusing the photos of Amelia Earhart and Charles Lindbergh when an older gentleman came up to tell me about Amelia lifting his sister into the cockpit of her plane. When I described why I was visiting, he talked about the little machine that they took around to high schools and fairs to show people the capabilities they had at the college. My first assumption was that he was describing a 3D printer…but then I really listened to what he was saying. Could it be a Handibot?!? (It was.)

Handibot on its jig, with blanks ready to head out for a demonstration about computer-controlled woodworking. Early on my first full day, I met Roger and several other instructors at the North Campus, and got a tour of the house that had been built by students and staff to be auctioned off as a fund raiser. NPCC started with a Handibot, then a local business suggested that they order a full sized tool so that they could train students to run the actual machines that are used in businesses in the community. In the wood shop, I spoke with an instructor who wasn’t keen on everything needing power and computers, so taught woodworking using conventional tools. His rocking chair is a piece of art. But he saw the value of the ShopBot when he realized that one of his students could use it, rather than a hand sander and jigs, to plane her thick slabs of wood quickly and evenly. Instructors from across the campus came to the classroom for an informal training, and we imported artwork from a book included with the new TorchMate plasma cutter to create files for the ShopBot, and vice versa. Faculty teaching theatre and other arts, as well as STEM education were invited to participate.

House built by NPCC faculty and students in building construction, HVAC, electrical and plumbing. This house has been auctioned off and a new one started. The ShopBot fabricated the arch over the Pella window.

Rocking chair made with traditional tools. This year’s Region 5 of ATEA was a smaller than expected (see below), with 50 – 60 people attending. As part of the conference, tours were arranged at local businesses. I grabbed a seat on the bus to Grain Bin Antique Town, where grain bins from the 1930s have been set up as storage units for carefully arranged antiques. The part-time endeavor has turned into a destination in the sand hills of Nebraska. Another businesswoman who runs Feather River Vineyards set up a wine tasting among the ladders, furniture and street signs in the main building. A former biology teacher herself, she noted the lack of younger people with the skills to continue the wine industry. Ryan Purdy, President of NPCC, perked up his ears and asked for more information on how the community college could fill that need. Roger Fattig raised the possibility of his woodworking program/ShopBot as a way to create customized gifts such as cutting boards for the Vineyard’s gift shop and wedding parties.

Grain bins from the ’30s recycled into storage units for consignment antique businesses.

View across the Sand Hills from inside one of the bins.

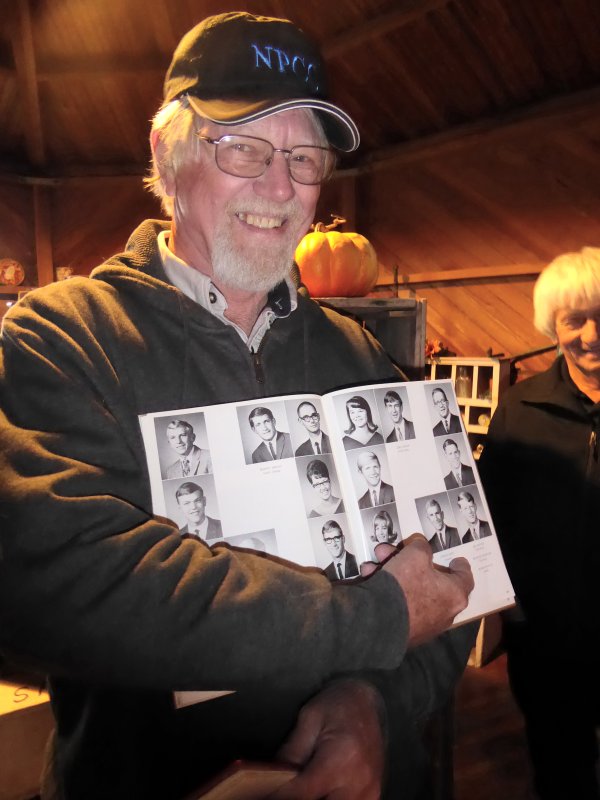

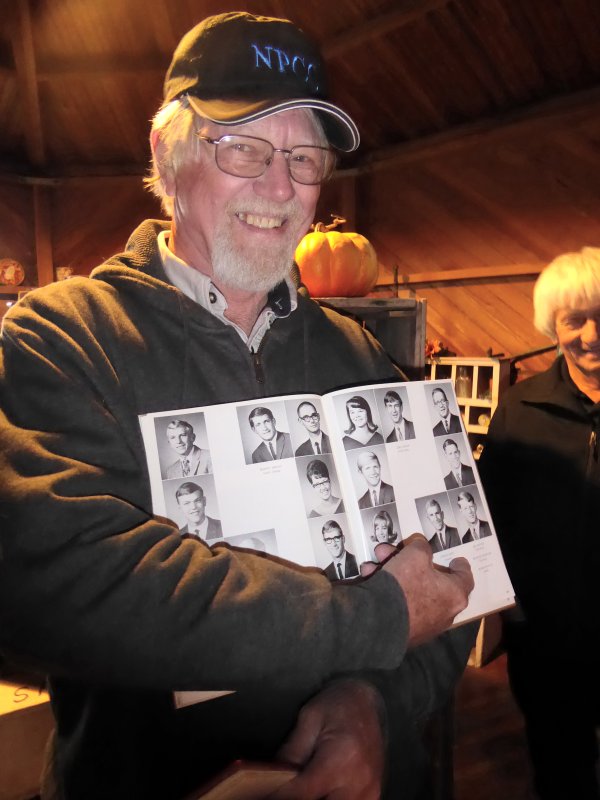

Roger Fattig finds an old yearbook with his picture from when he attended college in North Platte.

A selection of wines from Feather River Vineyards.

Wine tasting among the antiques.

Ladders, signs, wagons and leather.

Many people associated with the Community College have formed lasting relationships in the town. Roger and his wife, Melanie, moved to Oklahoma for a time, but moved back “temporarily” to help his father twenty years ago. They, two of their three children, and their grandchildren, love living in North Platte. The woman who runs the vineyard is married to the physician who is the family doctor for the Fattig family. While grabbing a quick lunch at a local fast food place, Roger caught up with a former student (the one who first mastered the ShopBot) as he went through the drive-through line. The head of the local museum (Buffalo Bill Cody settled in North Platte, World War II troops traveling by rail passed through the canteen) is really excited to hear that the ShopBot can carve topographic maps for displays for the museum, or create reproductions. Ryan Purdy, President of NPCC, has lived here all of his life, and can’t imagine living any place else. He is welcoming to newer industries in town, such as the breweries that are crafting beer. He was interested to learn that a makerspace in Portland, OR, ADX, has a fabrication group that takes on custom jobs, such as using their ShopBot to fabricate the pulls for the taps of many of the breweries in the city.

On the trip back to the college I asked President Purdy a few questions about the business of running a Community College. In the five years that he has been President, he has overseen a $3Million investment in the resources of the college, including updating the equipment and technology such as the ShopBot in the woodworking/building construction program and a TorchMate plasma cutter in the welding program. Funding for the college comes from three main sources: About 45 percent from the state, 35 percent from local taxes, and the rest from tuition. When I asked how he felt about Community College being tuition-free, he shook his head and said that the students “needed some skin in the game.” If they didn’t have some personal investment, they were more likely to start something and not complete it.

Region 5 of the ATEA includes colleges from 8 states, from Montana to Minnesota, and south to Kansas. The state of the economy affects the Community Colleges and the vendors who attend the meetings. For example, the drop in price in natural gas has resulted in South Dakota having their budget cut, and there were no travel funds to attend the ATEA meeting. Thus, there were few visitors to the vendor who was displaying equipment to train people to work with natural gas. Roger’s invitation to ShopBot to give presentations in how to use CNC equipment for everything from creating circuit boards to 3D milling brought faculty, administrators and students to the building construction area. It would appear that Community Colleges that have digital fabrication tools that can serve multiple audiences can respond to changes in local and national events.

Nowadays, we can all appreciate the chorus for re-shoring American manufacturing and hope that it may bring some jobs back to our communities. Yet there is an irony that, despite the wide recognition of our declining manufacturing base, proposals for manufacturing start-ups only grab attention when they are so compelling, so promising, that they can quickly scale to mass-production in China. Nowadays, we can all appreciate the chorus for re-shoring American manufacturing and hope that it may bring some jobs back to our communities. Yet there is an irony that, despite the wide recognition of our declining manufacturing base, proposals for manufacturing start-ups only grab attention when they are so compelling, so promising, that they can quickly scale to mass-production in China.

Current Heroes

The outsourcing of mass-production has become emblematic of success for our manufacturing entrepreneurs. Many of our institutions make heroes of those who scale to off-shored success. Venture capital PR, media hype, and government stimulus programs have helped spread a message that entrepreneurs should be valued for their visions of “high-impact products”, high-impact being little more than investor-speak for “high potential return”. We have created a counter-productive choice for our would-be manufacturing heroes that now hampers re-energizing local manufacturing.

New Opportunities

Affordable digital and robotic technologies for production are making small- and medium-scale manufacturing realistically competitive again. An enthusiastic case for a renewed manufacturing around these digital fabrication technologies has been called the “new industrial revolution” — by which small, digital-technology-based-businesses are seen as a possible core for a new manufacturing economy.

As an enabler of small operations, digital fabrication is more than a reprise of the hand-made, more than a sort-of super Etsy. Etsy does benefit from digital networks and logistics — the internet of wide-spread marketing and good shipping. But, the new-industrial-revolution concept takes networks and logistics only as a starting point, before more powerfully engaging digital design, digital product development and prototyping, digital control of machinery, digital collaboration, and digital data management to make small shops competitive again.

Less than half as many Americans are working in manufacturing today as in 1960. It is increasingly appreciated that this shift is due at least as much to technology and productivity efficiency as it is to offshoring. So it is unreasonable to expect that we’ll ever again have a large middle class supported exclusively by manufacturing jobs. More realistically, what we can hope for is some attractive new jobs in technology-based manufacturing — while we also re-embrace the importance of doing value-creating, innovation-spurring, production in our communities.

New technologies and our renewed engagement in DIY-making mean that there is an opportunity for re-invigorating manufacturing in our communities. Being productive does not need to be only about profit. Hands-on work that is rewarding, fulfilling, sustaining, and a source of value … that’s the spirit that we share with the makers and community blacksmiths of our history. Yet, the re-establishment of production in our communities is not inevitable. If we hope for it to re-emerge, we will need to be supportive of it. We will need to cultivate new manufacturing heroes.

This is an abbreviated version of the first in a series of articles on our manufacturing future and new fabrication technologies. Please see Full Article.

By Thea Eck, October 31st, 2016  Randy Johnson (upper left) greets the group as John Oliver (lower right) from ShopBot tech support looks on. The annual Michigan Camp ShopBot started in 2011 when a new privately-owned makerspace opened in Ann Arbor, MI. So many attended that it was easy to say, let’s do this again. Fast forward to 2016 and the Camp has become a yearly reunion for many, with 50-60 people in attendance. Though attendance was slightly lower this year, one could still feel the camaraderie in the room on Saturday, October 15.

The Camp now rotates between Maker Works in Ann Arbor and TechShop Detroit in Allen Park. And like most Camps, some were new to CNC and some were 10+ year converts. And since we were at TechShop Detroit, there was a great group of TechShop members, too.

Randy Johnson began the day with an introduction to ShopBot Tools Inc. and defined the CAD to CAM to machining workflow to give everyone a shared vocabulary. Thea Eck then lead several presentations including a new Understanding Nodes and Working with Text presentation. Both included how design (CAD) errors can lead to toolpath (CAM) errors and how to alleviate them. Randy’s Machine Maintenance presentation shined the spotlight on John Oliver from ShopBot’s tech support. John’s presence was a bonus to those troubleshooting their machines or design files.

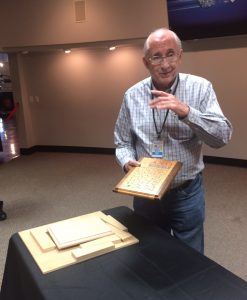

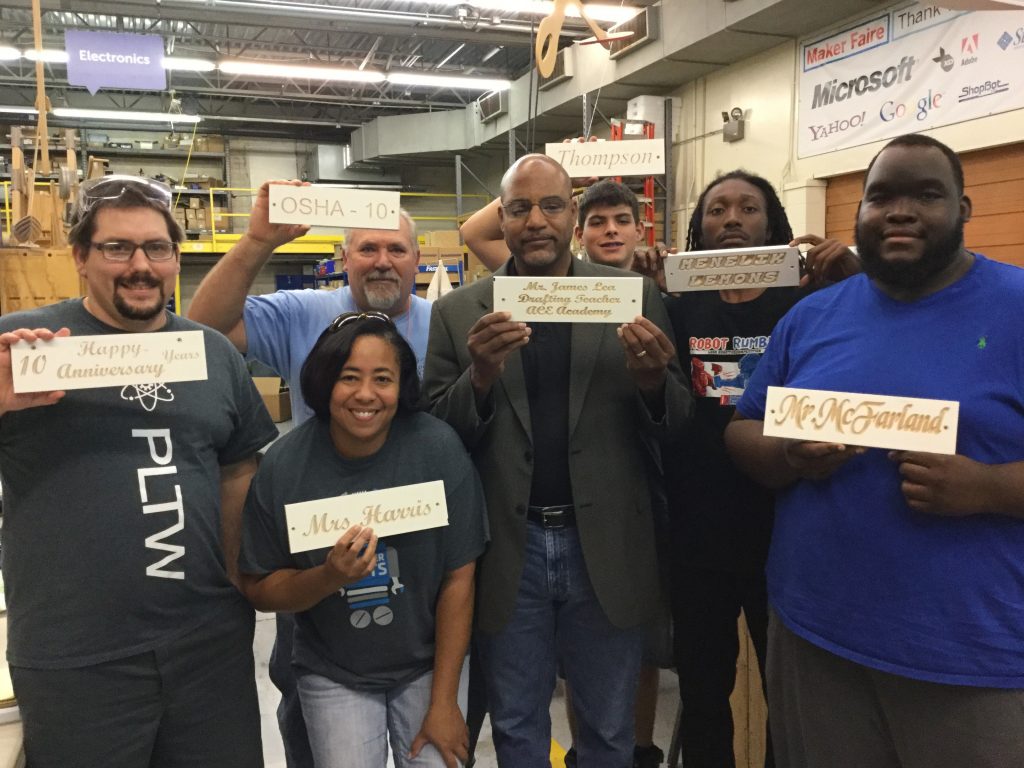

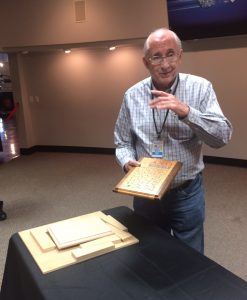

An attendee and TechShop member showing off numerous plaques he created for a friend using a jig design he learned in an Intro to CNC training ShopBot lead at TechShop Detroit in 2014.  Show and Tell Session during lunch

After lunch, attendees took the lead during Show and Tell. There were a few good examples of 3D carving. Randy then continued with a Textures presentation showing the import and trace bitmap commands and a little outside the box thinking to add textures to one’s projects. Thea wrapped up the day with Practices in 3D Carving. Attendees left not only with overloaded brains but they also received PDF copies of the presentations plus a few extra that weren’t covered due to time restraints.

The Camp season wraps up in mid-November with the Pittsburgh Camp. This year we traveled to 8 different locations around the U.S. Check our events calendar and also the TalkShopBot forum’s training/camps thread for Camp updates and announcements.

Another TechShop member discusses his machining process to create his wife’s new product.  The high density foam pieces are used as molds for vacuum formed packaging.

Great example of 3D carved clock.

By Tim Babiasz, October 17th, 2016

On October 8, the 2016 Charlotte Mini Maker Faire was held at Discovery Place Science. From audience to venue, the event played a number of roles. Local makers who had previously attended the event and others like it saw another opportunity to exhibit the things they were creating. For newcomers, it showcased the things that can be done with technology, art and everyday tools. In addition to these groups, the venue of Discovery Place proved more than adequate shelter from the wind and rain caused by Hurricane Matthew, which meant not only something to do for locals on a rainy day, but a great destination for those who had to evacuate from areas to the south and east and would otherwise be stuck in a hotel.

Sticker art installation at the Charlotte Mini Maker Faire

The final project for the Charlotte Makerspace, a dragon made combining CNC and 3D printed parts.

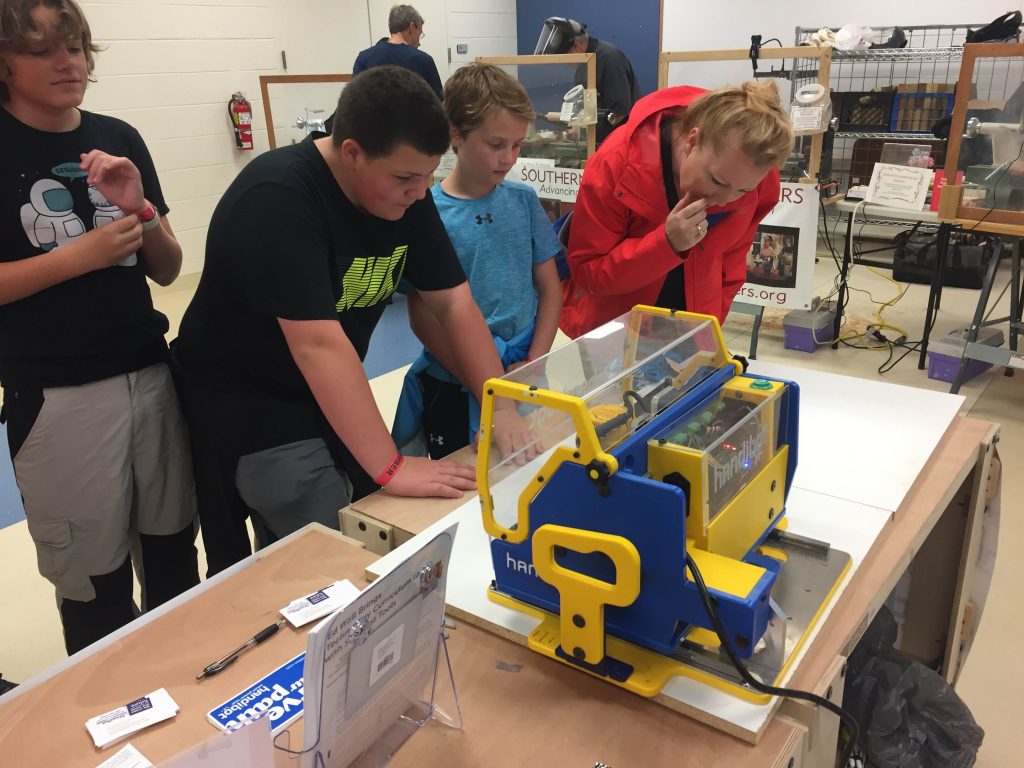

From ShopBot’s stance as exhibitor, this year’s Charlotte Mini Maker Faire was also different. Not only did they have the help of Eric Schneider, a local maker and Handibot owner from nearby Davidson, NC, but had to improvise the setup since the booth had been moved indoors (ShopBot’s was one of the stations originally planned to be outside on Tryon Street). The new location was Kids U, a multipurpose room that usually houses bugs, snakes and other critters, which were cleared out to spare them from the noise and crowd. The space was shared with Southern Piedmont Woodturners, a nonprofit organization dedicated to spreading the art and education of woodworking.

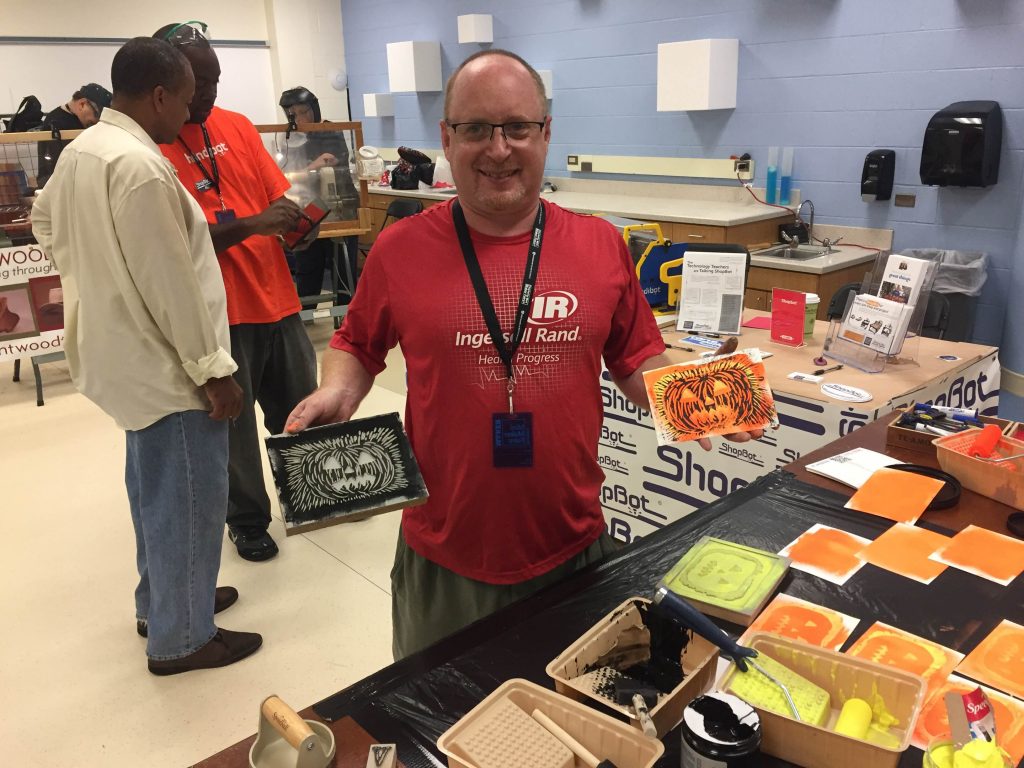

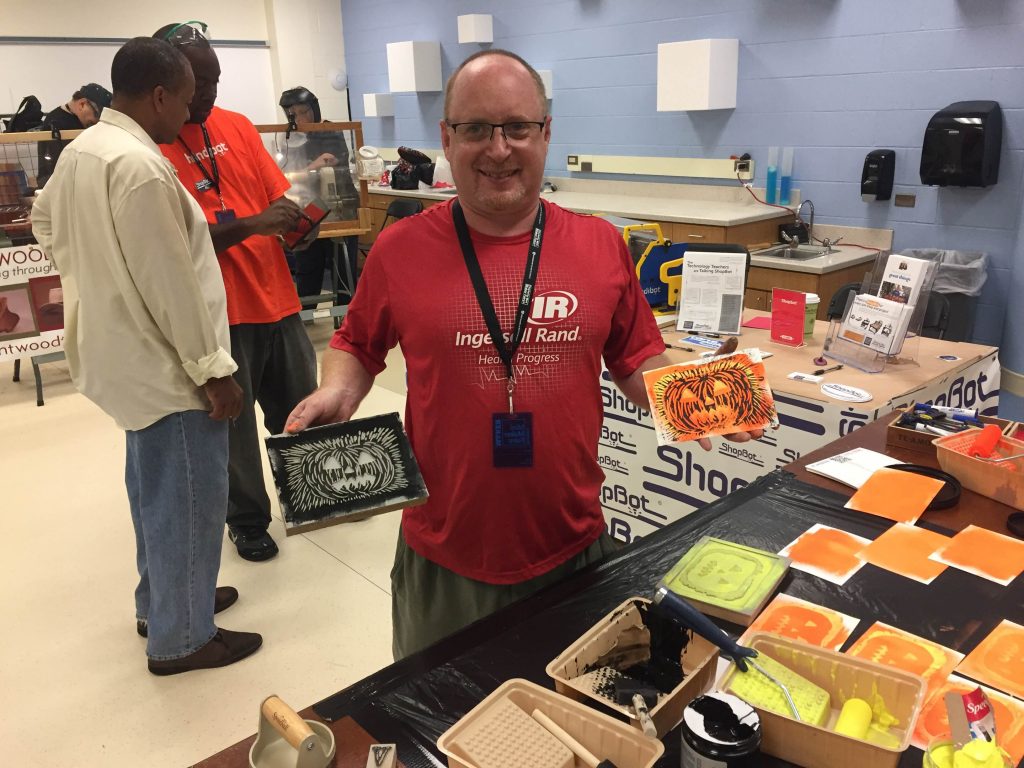

Kids U, before ShopBot & SP Woodturners takeover.  Eric poses with Handibot-made jack-o-lantern prints.

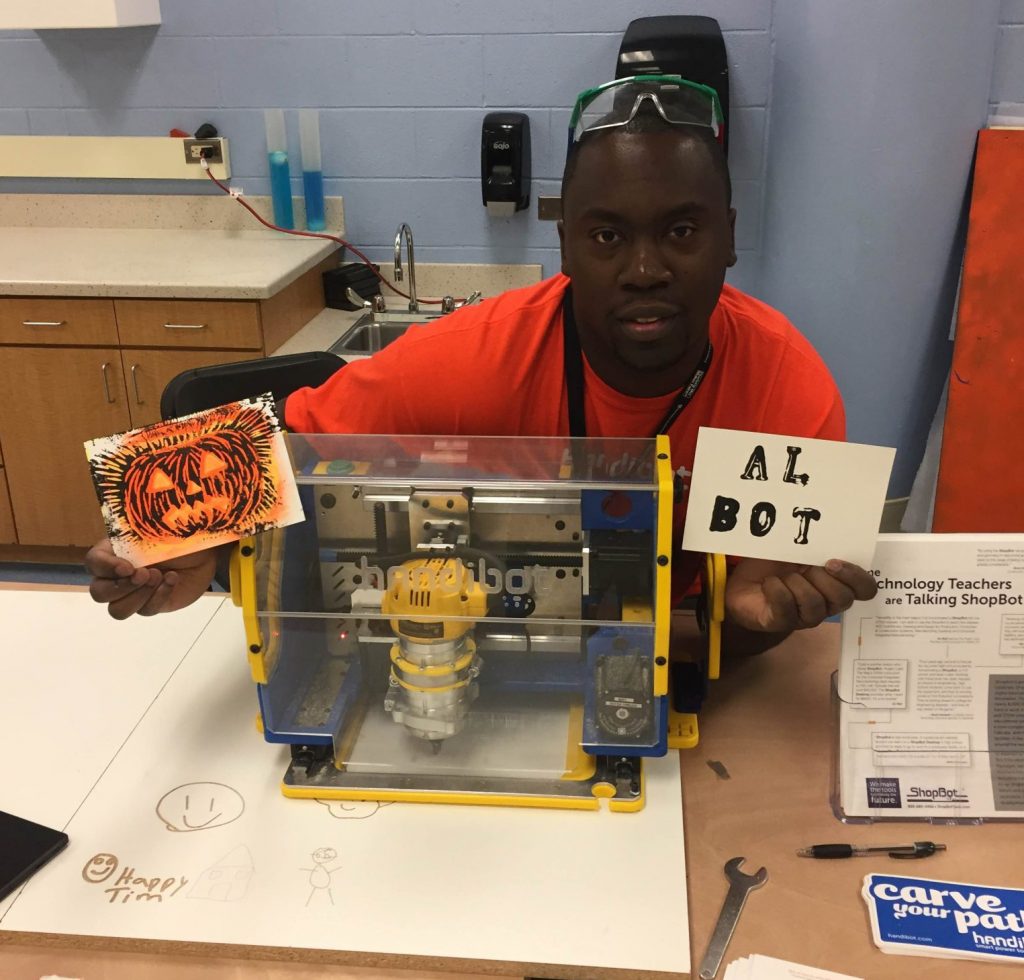

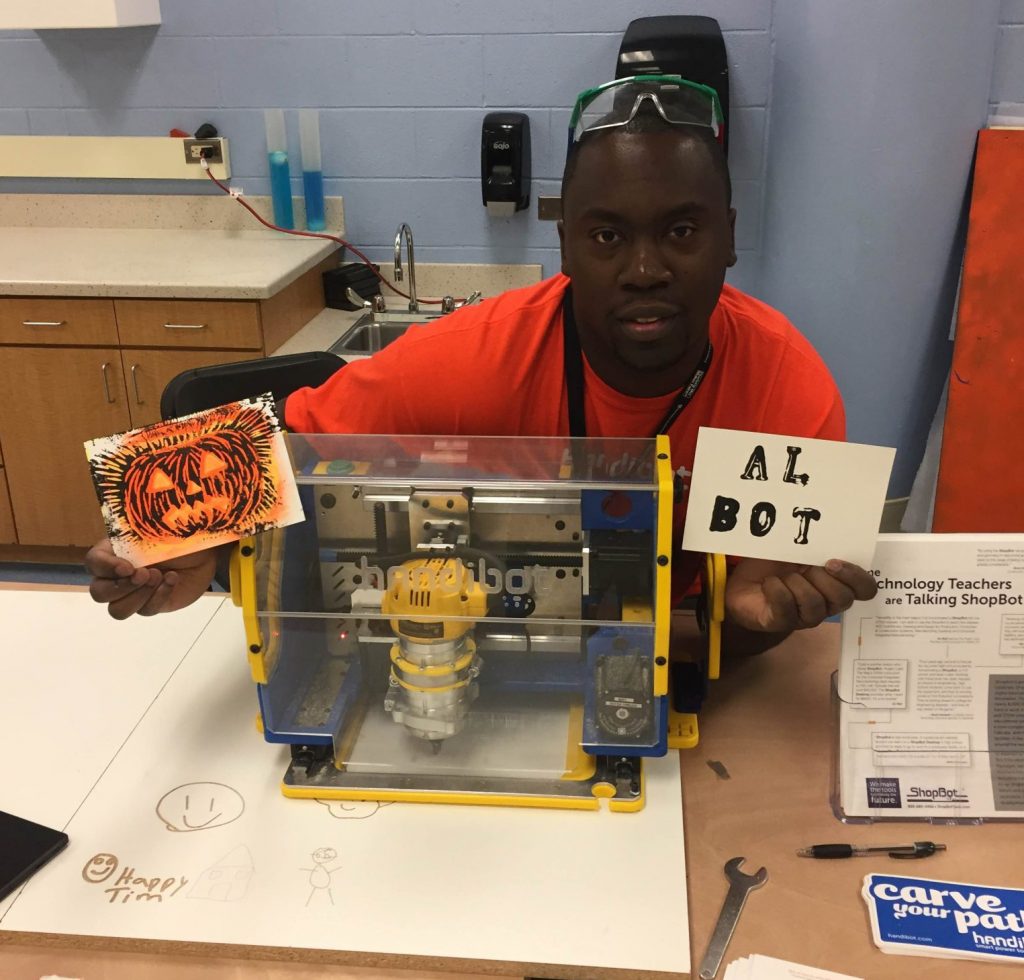

Discovery Place’s T. Rex shepherded traffic to Kids U.  Al poses with the Handibot and his Handiwork

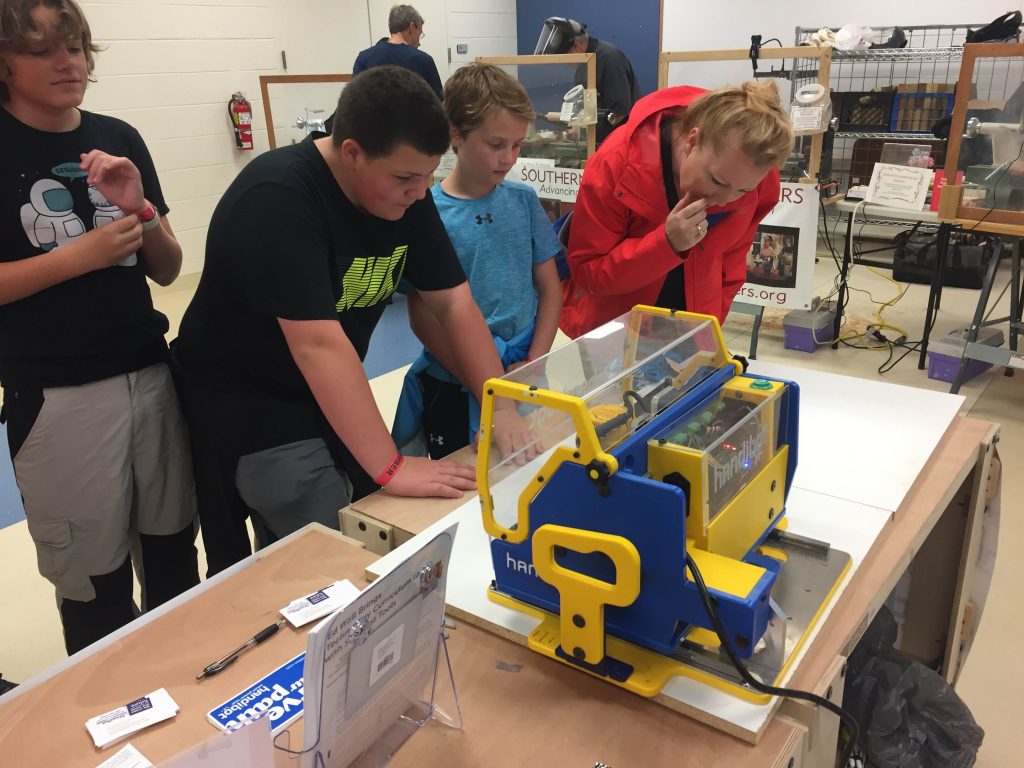

New technology meets a centuries-old process with Handibot-cut printmaking. In true maker fashion, the experience was defined by improvisation. With the new location, people would have a hard time locating both groups. Luckily, Discovery Place had a five-foot-long T. Rex they had cut on their in-house ShopBot. The dino was put to work right away to help guide visitors over to the station. Immediately outside the room, Eric set up his printmaking station. He cut a set of letter and character stamps on his Handibot, as well as a series of layered pumpkin prints that, when used in a certain order, created a striking glow-in-the-dark print that anybody could make. The stamps proved not only popular with kids, but made parents and makers wonder how they were cut and drew them into Kids U, where they could see the Handibot in action, cutting names and figures drawn in SmoothSketch with FabMo, ShopBot’s wireless interface software.

Kids and parents who had made prints outside were interested to come in and see how the Handibot worked.

Despite all the last minute planning and changes, the Charlotte Mini Maker Faire was a huge success. Rather than prove a hindrance, the rain and wind actually drove a new audience into Discovery Place Science. Makers from all over the Charlotte area and beyond were able to share all the creative and interactive things they were doing, which provided a day full of welcome distraction from Hurricane Matthew and its effects.

By Jeanne Taylor, October 11th, 2016

One of my favorite things about attending Maker Faires (large or small) is the moment you witness someone make the connection of how something is made—and then see the leap they make to quickly translating that new information to something they want to make. Maker Faires are ripe with individuals and organizations ready to show and share what they know to empower others to learn, discover, and participate.

The Maker Ed event on Friday, September 30th kicked off the 7th Annual World Maker Faire in NY. The event gathers educators together to grow hands on learning, create makerspaces, collaborate on curriculum, and more. Education spaces, from science centers to libraries, from hospitals to schools, to administrators and educators, are working with students of all ages and abilities to create environments that engage and activate young minds. During Maker Ed, we heard example after example of success stories: kids who were disinterested and checking out of school that undergo a change—they lock in on things like music, electronics, construction—finding their voice, interests, and talents. Events like this are encouraging for the future of education.

ShopBot had two booths this year for the Saturday/Sunday, Oct 1st & 2nd, event and a team of 6 ShopBot staff on hand. One of our booths highlighted the Handibot® Smart Power Tool Adventure Edition and its accessories. Our Smooth Sketch app brought out the artist in kids and adults alike. ShopBot’s Al-Solo Nyonteh and Clarke Barry had visitors draw with a finger on the tablet or phone, press “go,” and the Handibot carved out drawings while they explained what CNC is. It’s a quick way to make the connection between drawing on the computer (CAD) and having the machine cut, carve, mill, or drill your file (CAM).

Brian Owen, our lead engineer on Handibot, demonstrated using a jig that comes with the Handibot, to extend the work area by tiling and showed off the plotter pen attachment – a crowd favorite!

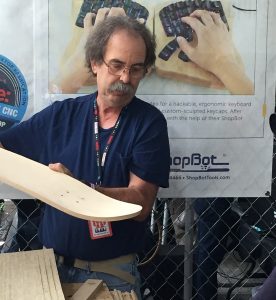

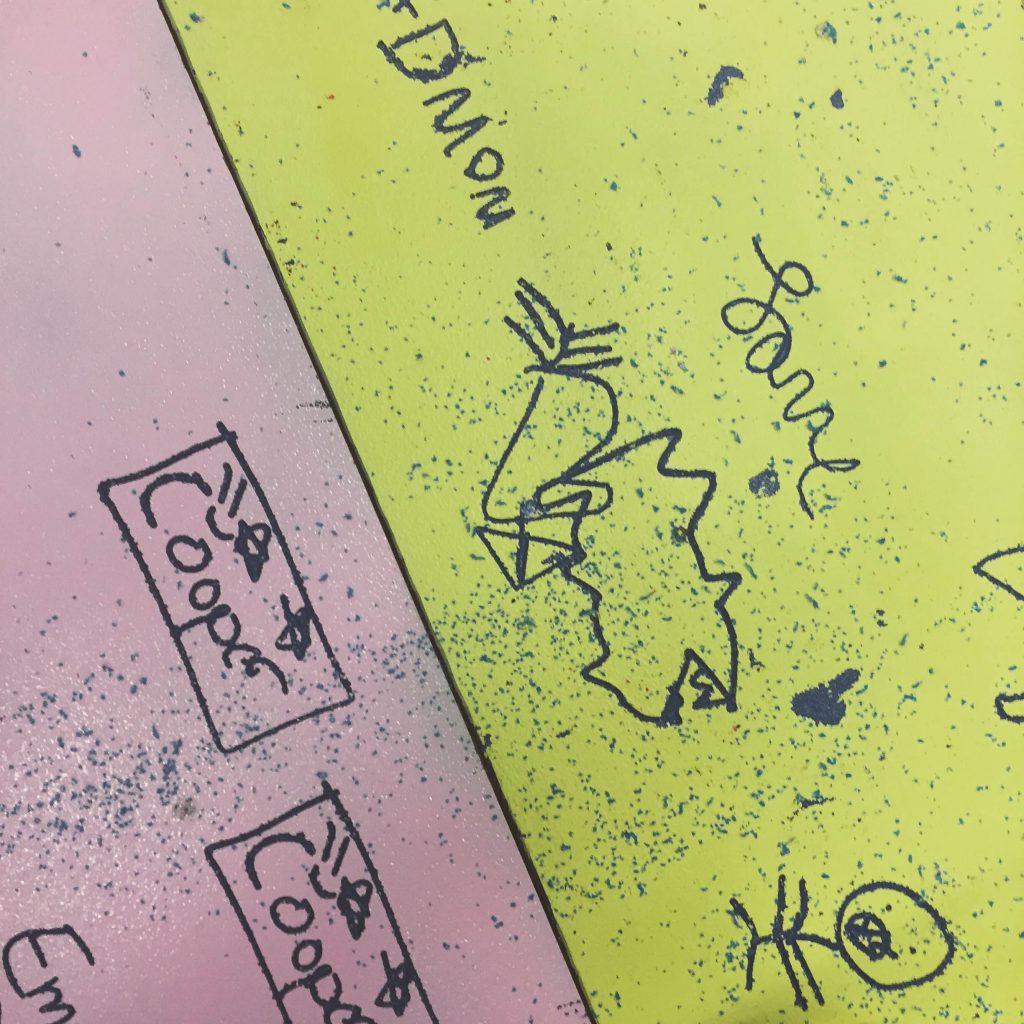

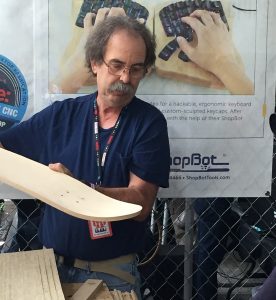

The second ShopBot booth was home to the ShopBot Desktop MAX. You can go from product idea to full production manufacturing with a ShopBot Desktop MAX. Its cutting area of 36”x24” makes it a great fit for everything from guitar making to signs to full size furniture parts. Our very own Bill Young created a couple of jigs to make skateboards, many which were cut throughout the Maker Faire. He showed the whole process from glueing up 1/8” baltic birch, to forming the wavy shapes in custom jigs (created on the ShopBot of course!). Every hour or so, he and Kevin Putvin, our lead engineer who designed the Desktop MAX, cut one of the boards profile on a special jig made to replace the entire table on the MAX. People flocked to see the boards come to life. We had several artists decorate boards before the event that were meant to draw lots of people to our booth—and did!

What an amazing playground for our future leaders, inventors, academics, and creatives. I’m glad ShopBot is a part of this movement and that we can play a role in helping people make their future.

See the World Maker Faire official slideshow.

Want the files to make your own skateboards?

Sign up here and when the files/instructions are ready, we’ll let you know.

Would you like to participate with ShopBot at a Maker Faire or event near you?

Event Participation.

By Thea Eck, October 3rd, 2016  Within 2 hours of receiving his Desktop, David had it up and running. David Sheffield was born and raised in Buffalo, NY. This city, like many Rust Belt towns, possesses a well-honed sense of pride for its sports teams and historical manufacturing contributions. David’s small manufacturing company, Buffalo Bottle Craft, creates simple products that let others around the country show pride for their sport teams, too.

Buffalo Bottle Craft makes bottle openers concealed in hockey pucks, baseballs and golf balls. Sold with a favorite sports team name or customized logo, David sells them to individuals and also has a thriving wholesale business. His 400 sq. ft. shop is located in The Foundry, started by a few of his friends. David’s manufacturing process utilizes the ShopBot Desktop model along with a Mimaki UV Digital Printer and a few other tools. Having already machined around 40,000 hockey pucks and 2000 golf balls in less than 3 years, David’s mastered machining these alternative materials.

The Puck Opener was David’s first product  The Baseball Opener is still made using a drill press

Trained as a mechanical engineer, David always wanted to start his own business. He gained exposure to many different processes including CNC while working for an engineering company that designs and builds assembly line systems. Making drinking glasses out of wine bottles was a good side business. But since each cup was handmade it wasn’t scalable. David is a huge sports fan, particularly hockey. After seeing a friend make a bottle opener out of round chunk of wood that looked like a hockey puck, he got an idea. Conferring with this friend, who wasn’t interested in making hockey puck bottle openers, he ventured into making them himself.

Initially David used a drill press. But again, the process wasn’t scalable. So began his hunt for an automated system, which brought him to ShopBot Tools. Compared to other CNC machines of similar size, the Desktop met his production needs. “I was looking for something I could pull out of the box and start up,” David reflects. “If you are doing small products like I am, having a full size machine doesn’t make sense.” In anticipation of its arrival, David watched a few video tutorials. And when the machine arrived, “I pulled it out of the crate, put it on the table and had it running within 2 hours,” he remembers. And with it running for 8 hours a day, the machine stands up to the challenge. A local company, Dynamic Saw, creates custom bits for him and his custom jigs help to machine 2000-3000 items for inventory.

Desktop set up with jig and hockey pucks  This photo speaks for itself.

Buffalo Bottle Craft’s website allows customers to use their own designs to customize his products. David can handle up to 3000 customized items in an order. David found this same customized service in ShopBot’s lifetime tech support. “That is what drove me to the original purchase, and the forum and how helpful everyone was there,” David offers. “Just being able to talk with someone over the phone, Frank or any of those guys, or send them a part file to look at” has been invaluable.

David originally tried patenting his product but found the process costly ($5000 for initial drawings and paperwork from a lawyer) and not necessarily helpful, and decided not to pursue it further. “The terminology the lawyers use is a defensive thing, not an offensive thing. If someone copies your patent, then you have to go after them. It is your money again,” he experienced. As David sees it, “instead of putting resources towards a patent I am trying to be the first to market, the best product offered, and get the most people to see it. My resources are better spent doing it that way than going after a patent.” He does have a trademark on the name, which cost him $2000 to do.

During the past 3 years, David also figured out the marketing side of things. Like many young entrepreneurs, he posted his first product, the hockey puck, on Reddit: It drove sales forward. He’s done this with each subsequent product, only posting 1 or 2 times about them. “Reddit readers don’t like it when you try to sell them something,” David says. His products were featured in various beer publications after he sent them an email and a free sample. David laughs, “I only started doing that actively at the beginning of this year and wish I had done that years earlier. It has really helped generate wholesale traffic.” With 30-35 wholesale accounts at any given time and constant re-orders, David created display cases, too, to hold more multiple items.

Buffalo Bottle Craft has it’s own website, and the products are also sold through Amazon, Ebay, Etsy’s wholesale branch, in stores and brewpubs.

The display cases are made using Baltic Birch plywood.  The Beer Wedge. All David’s products are magnetic.

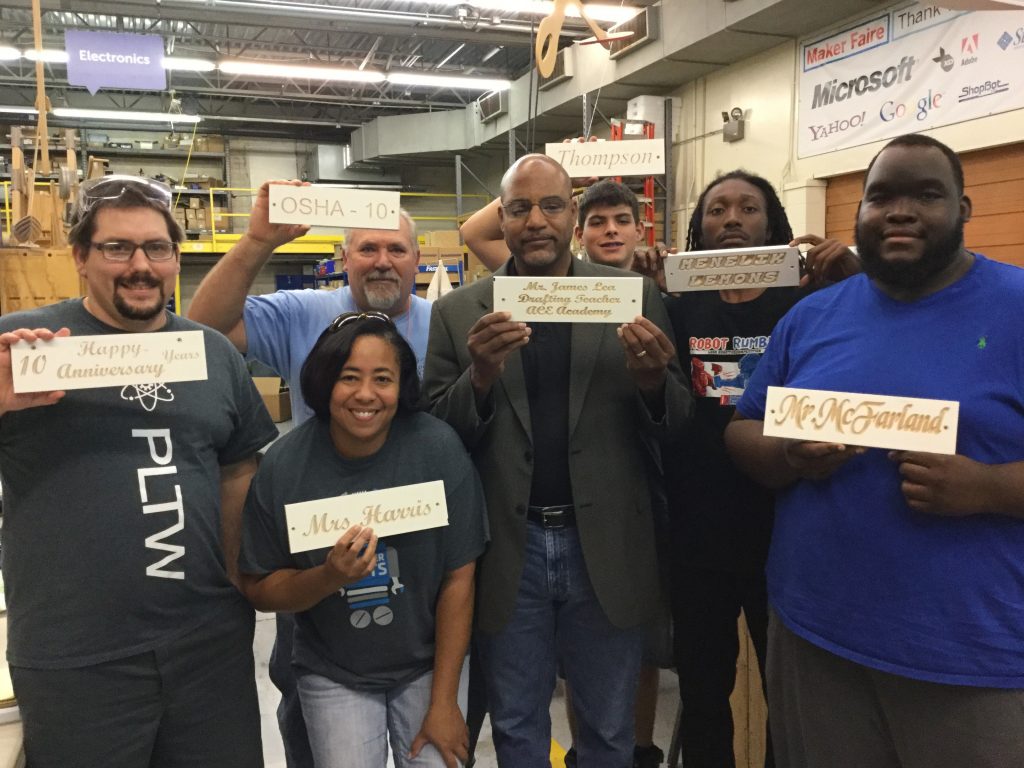

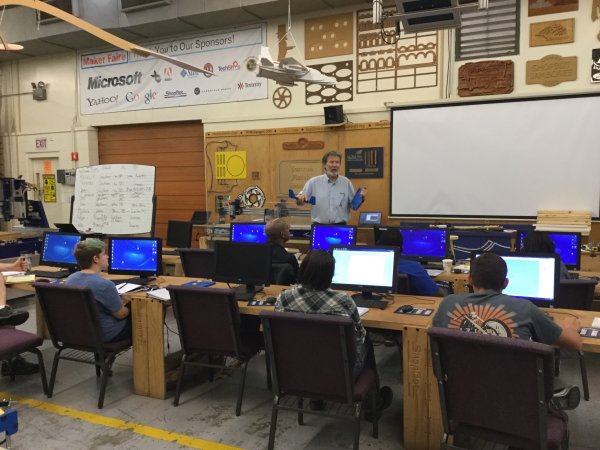

By Sallye Coyle, September 26th, 2016  Teachers and students with their finished projects When Rick Sheldahl, Career and Technical Education Director of the Durham (NC) Public School System, and Don Ramsey, carpentry instructor at Southern School of Energy and Sustainability visited ShopBot in 2014, they were looking for an affordable CNC machine that could help their students set up a production shop. Rick had budgeted about $25,000 for the PRSalpha with a spindle that would take a full sheet of plywood. ShopBot welcomes visitors and gives tours (with an appointment), but it is primarily a production facility and does not maintain a showroom. So the only full-size gantry tool available to demo was the 4′ x 8′ ShopBot used in the production of ShopBots, which includes the Automatic Tool Changer (ATC) and Vacuum Hold Down system. Don and Rick were smitten. With visions of training students for the work world, creating quality furniture that could be sold and the proceeds going towards scholarships for the students, and summer programs that would not be subject to the “bells” of the regular school year, Rick reworked his budget to purchase the full Production package for Southern High.

Fast forward to the end of the school year, 2016. Rick found himself with an opportunity to purchase CNC equipment for other high schools in the Durham Public School System that would be useful for CTE and STEM education. So, he ordered a number of the smaller ShopBot CNC machines: Desktops (24″ x 18″ cutting area), and a Desktop MAX (24″ x 36″ cutting area) with Rotary Indexer, Buddy (24″ x 32″ cutting area) with a 4′ power stick for the Production Shop. Then, he arranged for training for the teachers who might have found themselves with a piece of equipment that they had not requested, and had no idea of how or why they might want to use it.

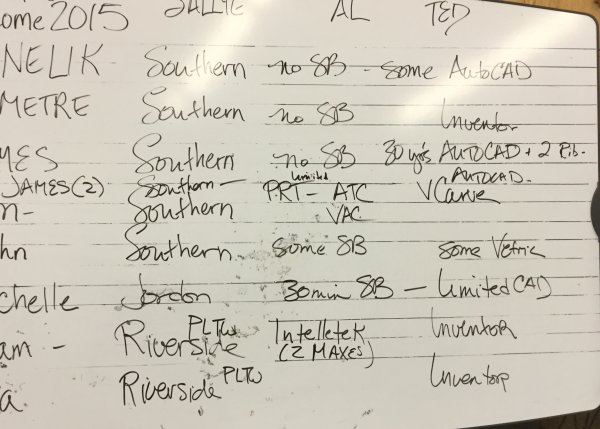

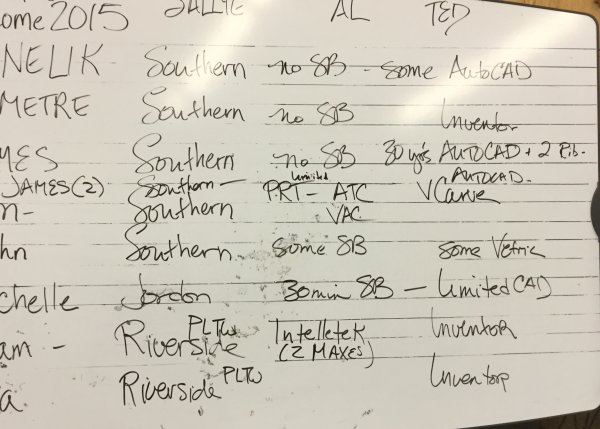

Background/experience of teachers and students from the Durham Public Schools (names cropped out to protect the privacy of students).

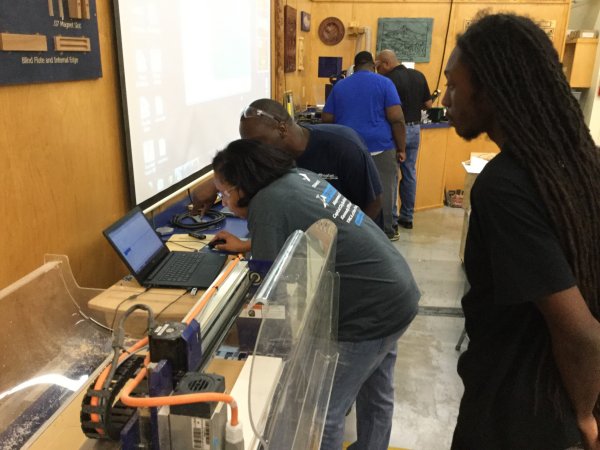

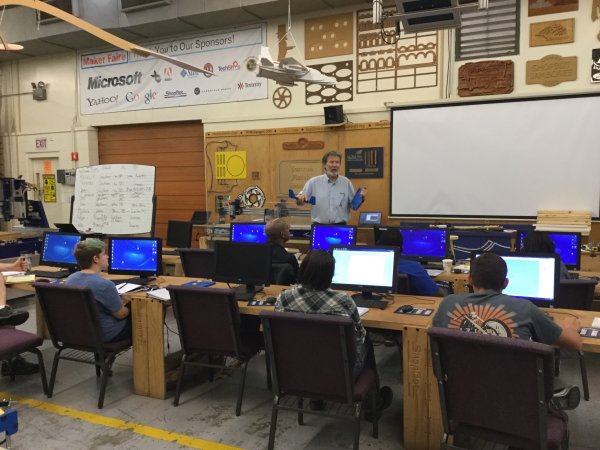

Training took place at ShopBot Tools on a Saturday in September 2016. Teachers and students from three high schools spent the day at ShopBot, getting hands-on experience with ShopBot Desktops and a Buddy. The background and experience level varied. Two teachers were coming from a very strong woodworking background, but with little experience using Computer-Aided Design (CAD) software. Michelle Joyner-Ricci runs the carpentry program at Jordan High School, and has years of experience with making things using traditional hand tools, power tools and mills. She had requested a milling machine that was adjusted by dialing in the measurements, and instead found a computer-controlled digital fabrication tool in her shop. Prior to the training, she had had a 30-minute introduction to the ShopBot Desktop and VCarve Pro CAD/CAM software at a CTE meeting over the summer. Don Ramsey and his student, a junior, came with a year’s experience using the PRSalpha Production system. They were ready to learn more about how to unlock the capabilities of VCarve Pro CAD/CAM software and the ShopBot.

The other three teachers were experienced in Computer-Aided Design (CAD) software such as Inventor, AutoCAD, and Revit, but had limited experience with how to take those designs and use Computer-Aided Milling/Machining (CAM) software to prepare them for machining on a CNC machine. Adam Davidson and his student from Riverside High School participate in the engineering curriculum, Project Lead the Way, which uses Inventor as its CAD program. The program includes PLTW’s CIM (Computer-Integrated Manufacturing) component to manufacture the objects designed in the 3D-rendering CAD software, but Mr. Davidson did not regularly use the older CNC machine they had at the school. Demetre Harris (Southern) uses Inventor, and James Lee (Southern) had 20+ years of experience using AutoCAD in the real world before singing on to teach AutoCAD at the high school level. Two other students from Southern also attended the class.

Instructors Sallye Coyle and Al Nyonteh introduced themselves and showed examples of the types of machining strategies possible with the ShopBot. Sallye also described the different types of bits used to create each of the strategies.

The ShopBot CNC machining at one depth (2D), engraving (VCarve) and machining in 3D (rounded 3D with pattern behind it)

Three general categories of bits are:

- End Mill Bit: flat on the bottom for machining at one depth (example: cutting through materials or pocketing to one depth)

- V-Bit: 60 or 90 degree for engraving or V-Carving

- Ball Nose Bit: round on the bottom for machining a 3D model

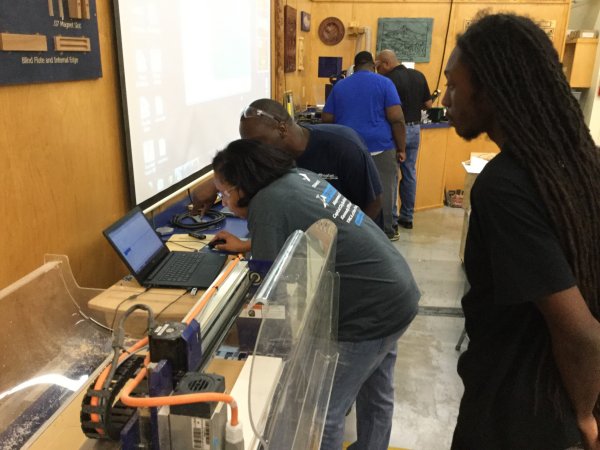

Hands-on experience with using the ShopBot control software to move a ShopBot around in X, Y and Z axes, and writing simple commands to tell the ShopBot where to go went a long way towards removing some of the mystery.

Moving the ShopBot around in the X, Y and Z axes.  Al and the teachers/students watching the ShopBot Desktop in action. A tour of ShopBot’s facility gave ideas of what kinds of careers are available at a small-scale manufacturing facility: everything from Production to Engineering/Product Design/Electronics, to Customer Support areas such as Technical Support, Sales Marketing and Business Administration. Throughout the building are examples of things that were made with a ShopBot: vacuum tables for holding down parts while machining, prototypes of aluminum parts for new products, signs made of acrylic that include moving parts and lighting with LEDs controlled by Arduino programmable electronics (shields or circuit boards machined on a ShopBot), desks that take advantage of ShopBot’s precision to make living joints (bendable plywood) or press-fit joints, ShopBots making Handibots. Samples machined in 3D with or without the rotary indexer were also a source of inspiration.

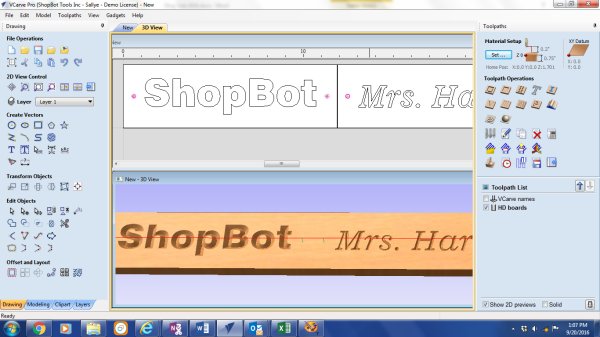

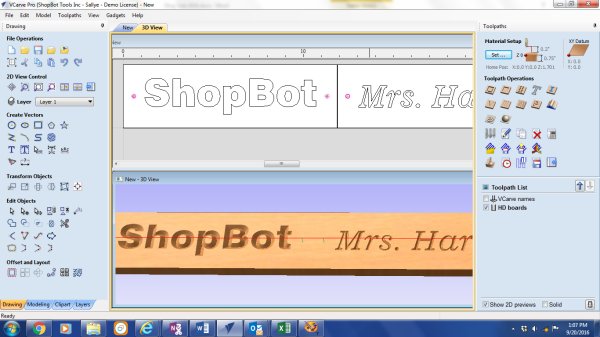

Working in pairs, teachers and students went through an exercise that demonstrated the entire process from design idea to finished product. They used the CAD ( what and where) side of VCarve Pro to design a sign, the CAM (how) side to toolpath the design so that it would look engraved, and generated the machine code that the ShopBot would use to move the tool in the correct paths. Included in the design and toolpathing options was an example of how to place hold down screws in the work piece so that the work piece would not move under the spinning router bit, and the spinning bit would not hit a hold down screw.

Using VCarve Pro CAD/CAM software to design and toolpath signs.

Teachers and students working with each other and ShopBot’s Al Nyonteh, to set up their files.

The Desktop carving a student’s file. Note the screws that are holding down the board for machining.

Each participant then set up a ShopBot to machine their sign. Using a checklist and printed instructions, and with the help of the two ShopBot instructors, participants changed the bit, zeroes the X and Y axes, and placed the material on the machine bed in the appropriate orientation, zeroed the Z axis, ran the files to locate the screw hold position, screwed down the material, and ran their sign file. Safety precautions were emphasized, an instructions on how to “Air Cut” a file before actually placing the bit in the material saved at least one router bit from being set down onto a screw and getting broken.

After lunch, Ted Hall, ShopBot’s Founder and CEO, gave a brief talk about ShopBot’s origins and capabilities. He brought over a Handibot, ShopBot’s newest product, and talked about FabMo, the open source Control System that is being written in-house. Several teachers/students talked with Ted while others finished their sign projects.

Ted Hall, Founder and CEO of ShopBot, gave a brief history and philosophy of ShopBot. Samples of items created with a ShopBot abound in the training area and throughout the company.

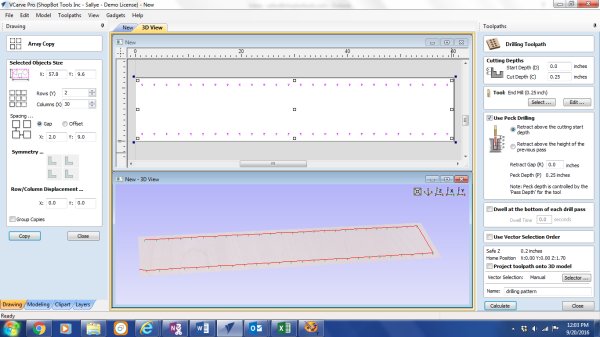

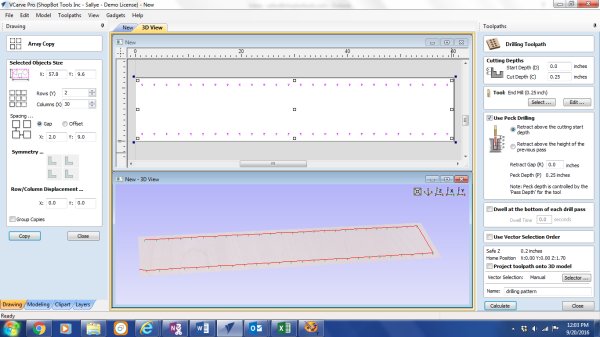

Once everyone in the room had completed their first project, the afternoon was open so as to give demos and information on how to successfully use the software or set up the machining files in the way that would be most useful for the individual teacher and student. Importing 2D and 3D designs created in another CAD software, feeds and speeds and bit selection for different materials, how to create an array of holes for cabinet making, and how to use the Rotary Indexer were among the topics touched upon. Participants left with a notebook full of instructions, and ideas for lesson plans and 2D & 3D projects that link to Common Core and Next Generation Science Standards.

Setting up a CAD/CAM file to machine holes in the sides of a bookshelf.

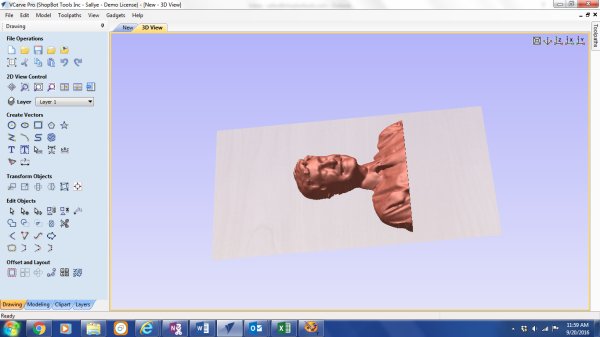

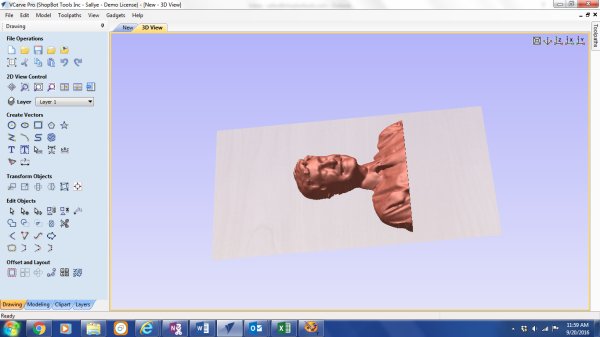

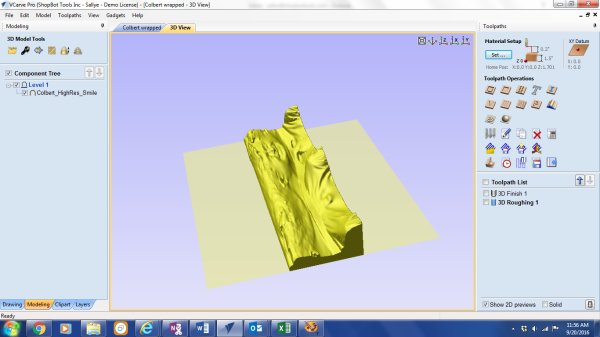

A 3D model of Stephen Colbert downloaded from the Thingiverse website and imported for 3D machining on the ShopBot.

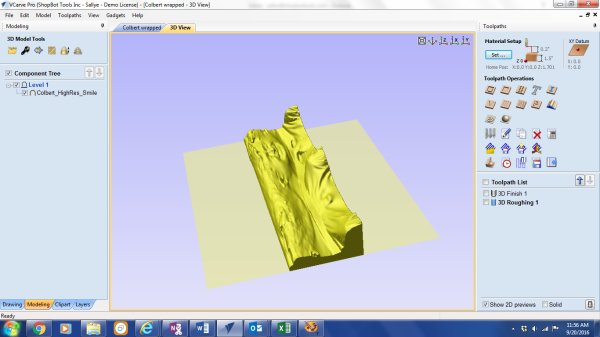

The same model being prepped (unwrapped) for machining in the round with the rotary indexer.

An example of carving in the round done on the rotary indexer. In this setting, students and teachers worked side-by-side to master techniques unfamiliar to both of them. The introduction of new technology often goes more smoothly when teachers are comfortable letting students take the lead in mastering new techniques and then sharing that knowledge with others. As the only teacher there with experience using the ShopBot, Mr. Ramsey proudly showed off pictures of the intricate signs that a young woman in his program had designed in Vectric’s VCarve Pro CAD/CAM software and machined on the ShopBot. She used the tutorials and videos available on the ShopBot and Vectric software websites to teach herself, and then others, sophisticated ways to import bitmaps (photos), trace them, and toolpath the designs. One of her files took five different bits, and the use of the ATC let her finish the project within one class session because she didn’t have to stop the ShopBot, then physically change the bit and re-zero the Z-axis in between the separate toolpaths. Mr. Ramsey also learned that it is important to have students from several grade levels work together so that his “experts” don’t all graduate at one time, and he has to start from scratch the next year.

At the end of the day, Mrs. Harris remarked that she was now more comfortable with the machine. SHe saw that there were many similarities to the 3D printer that she had used at the North Carolina Central University FabLab over the summer. Mr. Lee was not one of the teachers who had been given the gift of a ShopBot CNC, but left with information on what size ShopBot he would like to add to his classroom so that his AutoCAD students could actually prototype and test some of the designs that they had created on the computer.

A side note: many ShopBot employees attended local high schools in the counties that surround ShopBot headquarters in Durham, NC. Job positions range from Production through Engineering and Product or Software Development. Some employees started right out of (or even part-time during) high school, and some had internships at ShopBot before finishing their post-secondary education. Below are summaries of the journeys of three such employees:

Al Nyonteh, one of the instructors for the training, attended Riverside High School up to 1997 then transferred to a military school (Tarheel Challenge) for at-risk teens. After graduating in 1998, he studied architectural technology (a drafter that specializes on the architectural side of building construction) at a two-year college in Minnesota. Al worked in a commercial architectural firm for two years (in MN) and with an electrical engineer to create the drawings for the relocation of the electronics department at Circuit City (in VA). After moving back to NC, he worked as an independent contractor to prepare evacuation plans and submit health department drawings for group homes/alternative living facilities. Al joined the production team at ShopBot in 2014. He is motivated to learn everything about running a ShopBot, and often uses his lunch period and after-work time to design in VCarve Pro and machine on the ShopBot and Handibot. His gentle way of working with people and sense of humor make him a go-to person for in-house trainings, and when someone is needed to represent ShopBot at shows and Maker Faires.

Al Nyonteh, instructor, attended Durham Public Schools. He studied architectural technology in a two-year program in Minnesota. Al joined the production team in 2014, and is “fluent” in AutoCAD VCarve Pro CAD/CAM software, and running ShopBot tools using both ShopBot and FabMo control software. Matt Schmitz went to Durham School of the Arts, where he studied sculpture and theatre tech. He says it was a great place to learn about creative thinking and iterative design. Sculpture and theater tech led to an interest in product design. Matt studied Mechanical Engineering at Brown, graduating in 2014. In 2012, as a sophomore in college, he interned at ShopBot, and worked with CEO Ted Hall to develop the first functional prototype for the portable CNC that would become Handibot. He interned at Google during his senior year, working on the Nest Project (a high-tech smoke/CO detector). He currently works in Product Development, developing the next generation of ShopBots, and for Production Support, developing tools and solutions for clients with specific production needs.

Matt Schmitz, an engineer with ShopBot working in Product Development and Production Support, studied sculpture and theater tech at Durham School of the Arts. While a student in Mechanical Engineering at Brown University, he did internships at ShopBot and Google.

Lee Beatrous attended Cedar Ridge High School (Orange County, NC), taking two years of woodshop class with instructor Keith Yow. Lee furthered his education at Appalachian State University. He started with a focus on Business Marketing but changed direction by entering ASU’s School of Technology and earning a BS in Industrial Design. After winning a Popular Design Vote at the High Point Furniture Market in a sponsored studio competition, Lee went on to work for GSI – a furniture manufacturer in Dallas, TX. He held the position as Project Design Manager for five years. Lee is currently working for ShopBot Tools at Handibot as a Manufacturing Engineer, seven years after working a summer internship at ShopBot in the Production department.

Lee Beatrous, Manufacturing Engineer for Handibot, took wood shop classes while at Cedar Ridge High School in Orange County, North Carolina. He studied Business Marketing and then Industrial Design at Appalachian State University. In this photo, he is using the plotter pen attachment to draw on a skateboard. The bed and holes for the trucks on the skateboard were cut on a ShopBot, then formed into the shape of the board.

By Tim Babiasz, September 22nd, 2016

Catching Up with the NODUS Team

When we last checked in with Gustavo Bonet and the NODUS crew, they were using digital fabrication to realize project visions that ranged from architecture to furniture to art installations. In that time, NODUS’ reputation as a “fixer” has grown, allowing the team to move into a new space in Manhattan’s SoHo neighborhood that simultaneously serves as a gallery, collaboration area, and workspace. The space is designed to embody NODUS itself, reflecting the changing idea of what a workspace can be. For NODUS, this move doesn’t mean a change in the type of work they do, it just means more flexibility and fewer obstacles, and increased notoriety in the digital fabrication and design communities.

The New Space

The SoHo space will house the NODUS team, host alternative events, and display finished works. In addition, it will allow the team to explore new avenues in design, architecture and art. One of the scheduled events, for example, will feature a pastry chef who will explore the idea of the modern kitchen. With projects like these, Bonet’s team is focused on pushing boundaries. “We’re thinking outside of the box, and we’re at the cutting edge as far as workspaces go, transcending the realm of furniture or industrial design. It will feature things that will enrich your day. We’re catering to things that stand out.”

A Unique Take on the Design Process

On a day-to-day basis, even the role that their ShopBot plays in the process is unique. It’s seen less as a mass-production tool and more of another potential solution to meet the needs of the project at hand:

“We’re architects using the tools in a very hybrid way,” says Gustavo. “We’ve learned the basic commands and can approach projects from a problem-solving architectural standpoint. With proximity to the tools, adjustments can be made on the fly. We’re bridging the gap between art & architecture.”

bOcean Resort

The bOcean resort lobby reception wall was inspired by blades of seaweed swaying in the ocean.

One of the best examples of such a project is the lobby reception desk installation at the bOcean Resort in Fort Lauderdale, FL. Charged with designing a carved wood installation that would mimic seaweed swaying in the ocean, the NODUS team also looked to complement the art deco and features dotting the resort, as well as the storied mermaid show featured at the lobby bar, from where the upstairs pool is visible.. Their solution was an 8’ x 24’ surface comprised of 21 individual pieces, each cut on the ShopBot and assembled on-site like a large puzzle.

The Dwana Smallwood Performing Arts Center

With projects like the Dwana Smallwood center, NODUS is re-thinking the way CNC can be used for design. For the Dwana Smallwood Performing Arts Center between the Brooklyn neighborhoods of Bushwick and Bedford-Stuyvesant, Nodus worked with architects at JPDA to develop a surface relief for the facade and interior echoing the rhythmic quality of a dance gesture rippling out, impacting its surroundings.

For the interior reception area, Nodus milled solid fiberboard panels tightly coordinated with the surrounding millwork for seamless integration. On the exterior facade, custom-cast, glass fiber-reinforced concrete panels provide graphic identity for the dance center, and continuity between exterior and interior.

For interior panels, Nodus prepared fabrication models, and surface milled fiberboard directly. For exterior panels, concrete forms were developed through an analogous process, then cast by hand.

Analogous process, in which the cast was carved to mold concrete  Stirring the concrete for the external facade pieces.

The internal installation, which was cut and assembled piece by piece.

Hines Fischer Furniture Prototypes

For the ICFF Studio 2015 Competition, Nodus worked with industrial designer Hines Fischer to fabricate prototypes for his Minun series. Nodus performed two-sided milling of all wood components and joinery included in the piece.

Two-sided milling of furniture pieces created a 3d effect.

Designing the Future

As to how NODUS sees future projects taking shape, it’s all about staying innovative.

“There’s no limit,” says Bonet. “It’s the idea of a workspace that’s changed, and it’s truly a collaborative environment/gallery/showroom. We’ve become the keystone of the industry, and what is rewarding is we’re seeing more and more people starting to respect and appreciate our role in the process.”

The NODUS team may be beginning the next chapter of their story with the SoHo gallery, but the main theme is always going to be collaboration and problem-solving. You can check out their latest projects on the nodusNYC website & Instagram, and stay tuned to ShopBot Tools for the latest updates!

By Thea Eck, September 19th, 2016

TechShop DC/Arlington served as a great host location for the first ever DC-Arlington Camp ShopBot. Situated across from Reagan International Airport, a large and varied population utilizes the space and tools. And with three different models of ShopBot machines and array of other machines their members are not lacking in digital fabrication resources. One can tell that Gadsden Merrill, General Manager, and his staff work tirelessly creating an energetic environment.

The ShopBot team comprised of Sallye Coyle, Reggie Riddit, Thea Eck, Bill Young, and guest presenter Andy Pitts. Attendees drove in from as far away as Eastern PA and also from Baltimore and the surrounding Virginia communities. Experience ranged from absolute beginner to professional user with years of CNC practice, many types of material cut, and multiple Camps attended. And being at a makerspace, curious TechShop members popped in and out all day.

Sallye began the day discussing CNC and CAD/CAM along with the cache of digital fabrication tools now available to the average maker that aid in prototyping or embellishing projects. Thea then lead the group in several presentations including highlights of Vectric’s new Aspire 8.5 and how to calculate the dreaded feed rate and speeds for a project. Sallye showed some hidden gems in the SB3 software, which are often overlooked or not fully understood. Lunch gave everyone the opportunity to mingle, look around TechShop’s studios and talk one on one to ShopBot staff.

Following lunch, the Show and Tell session offered a few volunteers the chance to present their projects. Andy Pitts then launched into the afternoon presentations explaining how to set up a CAD file and then machine a two-sided bowl using Aspire software. Though simple upon first inspection, this complex bowl shape utilizes multiple two-rail sweeps and 45° 3D machining techniques. Sallye and Thea followed up with two presentations on 3D machining: 3D scan to 3D machining and practices in 3D designing/machining starting with the basics such types of bits and understanding stepover rates.

Bill Young discussed and then demoed FabMo, a new development currently used to operate the Handibot. Bill chimed in throughout the day with his expertise on a variety of material, software, and machining topics. The final presentation, machine maintenance and troubleshooting, got everyone out of their seats and crowded around TechShop’s PRS Alpha 4×8.

Like many Camps, the day sped by. Often times conversation came back to pricing items and calculating costs: electrical costs, material costs, production vs. custom items, how much to pay oneself and working with clients. Everyone seemed to gain new insight, some ‘hidden gem’, personal to them that will hopefully make machining or designing a little easier.

Thank you to the TechShop DC/Arlington staff and to the attendees for spending their Saturday with us.

The Wood shop. Each studio includes an array of tools, both traditional and digital.

TechShop DC/Arlington has three different ShopBot models

Andy Pitts explained the jig he used to register his two-sided bowl.

Bill Young showed off the Handibot.

By Sallye Coyle, September 8th, 2016  Friends from 5 Continents sharing one last evening at SZOIL after Fab 12 in Shenzhen. The Location: This year’s gathering of the International FabLab network took place in early August in Shenzhen, China. About an hour from Hong Kong, Shenzhen is a new city, grown up in the last 25 – 30 years from a fishing village to a modern industrial and commercial center. Except for the signs in Chinese characters, the view from my room on the 22nd floor of a hotel in the financial/convention district looked more like an American city than many international cities built on top of older civilizations: traffic was organized in proper lanes, turns signals flashing, horns blaring. Shenzhen’s location close to Hong Kong, the numerous factories to manufacture whatever it is you need, and the amazing network of creative spaces around Shenzhen made it the perfect location to hold the meeting.

Those FabLabbers with a bent towards creating their own could fill a suitcase with motors, drivers, boards, cables, or purchase real or knock off phones, cameras, projectors, and watches in the electronics markets. The shopping malls carried name brand clothing, shoes and purses from around the world, as well as motorized carts in the shape of animals for the kids to ride around the mall. Many malls had DIY sections, with build-your-own music boxes, pottery wheels, and painting classes. Grocery stores had Lays Potato chips bags with funny faces on them, cans of soda with the name in the familiar Coco Cola font as well as Chinese Characters, Dragon fruit, and chickens with head and feet still attached.

It seems that the crane is the national bird.  Adam (New Zealand) and Frosti (Iceland) explore the electronics market.

Traffic in Shenzhen is orderly, though horns are in constant use.  Sunday afternoon at the mall is a family affair

The Meeting: The annual Fab gathering is an important vehicle for building and maintaining the network of FabLabs. It is also a celebration honoring the graduates of Fab Academy, the 6 month long course based on MIT’s “How to Make (Almost) Anything.”

Mornings were filled with reports on the doings of FabLabs around the world, and announcements of interest to the greater community. And there is always Fabbercise, which can have its own share of familiarity and hilarity.

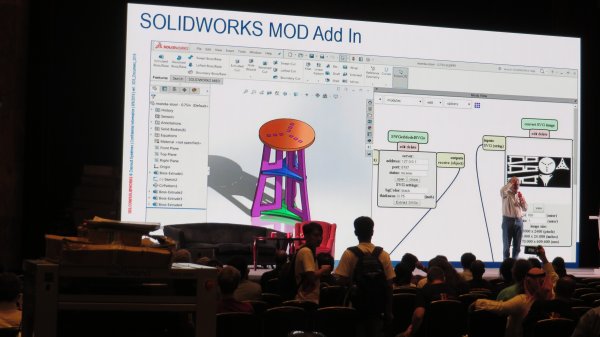

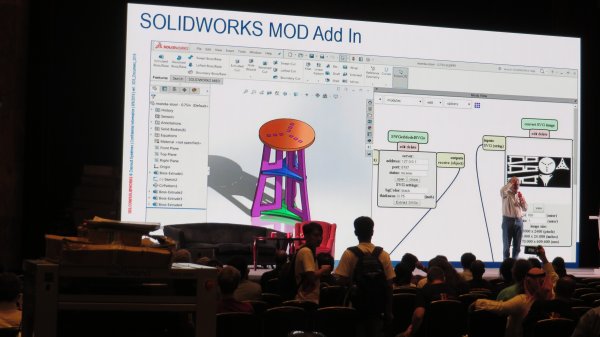

Motorized scooter created at FabLab Hamamatsu, Japan. A ShopBot was used to cut out the MDF parts of the body.  Solidworks introduces an add-in for Fab Modules, Neil Gershenfeld’s software for running digital fabrication machines in the lab.

Fabbercise, led by Walter and others of the crew from Peru, weaves the audience into a web of laughter.

Afternoons brought options for workshops and sessions. Want to use a laser cutter to create hats or lamps? There’s a workshop for you. Want to discuss topics in education or humanitarianism? There’s a session for you. Want to catch up with old friends and make new ones? There’s plenty of time to connect, collaborate and share. Evening meals and after gave more opportunities to learn what is happening in FabLabs around the world. There was even the opportunity to see how products developed in a FabLab can be brought to market when 3NOD, one of the event sponsors, hosted a fabulous evening at their headquarters.

Lanterns demonstrate Chinese traditions, plus laser cutting and circuits for the battery-powered lights.  Bas (Iceland), Ohad (Israel) and Jean-Luc (USA) connect over workstation for creating new digital fab tools.  Ohad (Israel) and Wendy (New Zealand) show off hats made in their textiles workshop.

HotPot with Katy and Jennifer from FabLab Santa Clara

Dinner hosted by 3NOD.

Products brought to market via 3NOD, Shenzhen.

The focus of Fab12 was FABLAB 2.0, the ability of a FabLab to use its own digital fabrication tools to produce a fab lab and to produce the manufacturing machines of the future. Since the Handibot (www.handibot.com) was inspired by work of MIT students under the direction of MIT Professor Neil Gershenfeld, Center for Bits and Atoms ( www.cba.mit.edu ), it seemed only proper that a Handibot traveled to Shenzhen to take part in the festivities. Others brought their version of a digital fabrication tool created in a FabLab. Jens Dyvik used the ShopBot in the Shenzhen Open Innovation Lab (SZOIL) to fabricate parts for his VBird parametric CNC, and Steven Sui made his multipurpose CNC machine with GCC products such as the laser cutter and CNC machine. Nadya Peek offered workshops on how to create digital fabrication tools from cardboard kits and component motors and rails.

Handibot’s view from the hotel room on the 22nd floor.

Jens Devyk (Norway) conducted a workshop on using a large format CNC (ShopBot) to create a parametric CNC from plastic and MDF. You can see a video of Jens’ VBird CNC machine and software here.

Handibot with Steven Sui’s U-Bot, a small CNC with the option to change out a 600 rpm router with a laser head.  Detail of rack cut on ShopBot for VBird parametric CNC.

The Symposium: Friday’s symposium, open to the public, addressed 4 topics that scaled from the individual to the civilization.

- Systems That Make Systems

- Businesses That Make Businesses

- Organizations That Make Organizations

- Civilizations That Make Civilizations

The Fab Festival: The weekend event, open to the public at the Civic Center, was a celebration of all things Fab.

FabLabs in Peru are working with indigenous people to retain knowledge about such skills as weaving and furniture making. There is also a floating FabLab on the Amazon River.  FabLabs in India range from those at an Engineering University in Mumbai to an Ashram in the country that emphasizes project-based learning. Projects include how much it costs to raise animals, or create machinery that enhances lives. In Kerula, there will be 20 mobile FabLabs distributed around the province, each with a ShopBot Desktop.

Jens’ finished CNC at Fab Fest.

FabLab Barcelona has a strong program in textiles. Barcelona has a commitment to creating a “smart city” in which there are multiple, localized fab labs so that people can create what they need rather than import goods and export trash.

Folks from France and India at Fab Fest. Fab 13 will take place in Santiago, Chile, and Fab 14 in Toulouse, France.

ShopBot Sallye at Fab 12:

ShopBot and FabLabs have had a strong relationship for a number of years. ShopBot is a CNC of choice on the official FabLab buy list, so attending the Fab meetings is an opportunity to keep up with the exciting advances that those who participate in the FabLab network are making, offer training and tech support where needed, and learn what ShopBot needs to pay attention to in order to better serve the community. After 6 years of working with FabLabs, I feel that I have a growing network of contacts that works both ways. If someone has a question, they have my direct email and a cell phone number to call. Likewise, if a ShopBot user or ShopBot Tech Support needs a local representative to serve as “boots on the ground”, I have an idea of who has ShopBot experience that we can reach out to. Our plan is to expand that network and make it more accessible…look for an update to the ShopBot website in a few months.

It is always a bit surprising when someone refers to ShopBot as a “vendor”. We think of ourselves as friends and colleagues who just happen to manufacture an amazing CNC machine. Arriving a few days before each meeting is an opportunity to make new friends, pay attention to how people are actually using the machines, as well as to make sure that the local ShopBot is in proper working order for the meeting. For Fab 12, the ShopBot at SZOIL was mostly assembled, but Francisco S (Beach Lab, Sitges, Spain), Vicky (SZOIL) and I spent several hours resolving some Control Box/Spindle issues before laying down the support and spoil board. Since Francisco will be one of the trainers going to Kerala, India, to help with their deployment of 20 mobile FabLabs, he got some hands-on experience with hardware and software. Vicky, Fab Manager at SZOIL, began to take ownership of her ShopBot when she used a ratchet wrench for the first time to tighten the hardware for the support board. We ended the late night by taking a 3D scan that Vicky had created for printing on the 3D printer and machining it on the ShopBot.

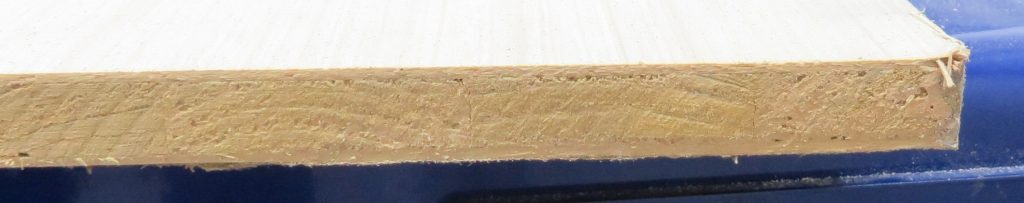

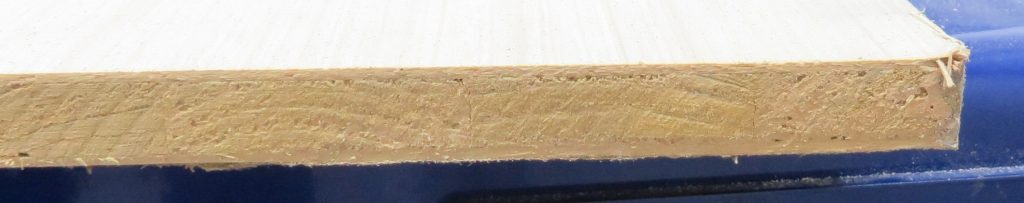

With each international trip, I learn a bit more about how ShopBot is used outside of the US. Some lessons are not related to the ShopBot itself, but point out differences in the operating language of the computer, or electricians deciding to run the power to the control box in a way that does not conform to the specs of the tool. It can be a lesson about the types of material available locally. For example, in Shenzhen, there were two different kinds of sheet goods available in the lab. While both were referred to as “plywood”, they had very different characteristics. What I would call “plywood” is made up of thin layers of wood laid down with the grain rotated 90 degrees at each layer (ply). It is less resistant to changing size as the humidity level changes, and maintains a certain level of structural when dadoes or slots are machined into it. Sheet goods that are made up of long strips of solid wood glued up and covered with thin veneer may be more consistent in thickness than plywood, but it can lose its structural integrity as soon as the thin veneer has been machined through. I have never seen this type of sheet good in the US, but have now found it in Japan, Egypt and China.

Vicky, Fab Manager at SZOIL, tightening down the ShopBot support board.

Vicky’s first project with the ShopBot. She added bunny ears to the original .stl created from a 3D scan, then carved it on the ShopBot with a .25 ball nose bit. See our previous blog entry for the process to convert a 3D scan to a 3D ShopBot carving.

With “plywood” (above), thin layers of wood are peeled off of a log, laid down flat and laminated together. One does not have to pay attention to the grain of the sheet good when assembling cabinets or tables, since the grain of each “ply” is alternated 90 degrees to reduce the effects of changes in humidity level on size of each component.

The second type of sheet good is made of up solid strips of wood that are glued up the length of the board. Note the growth rings on the edge of the board. Only a thin layer of veneer adds strength to the glue up. Creating a dado or machining a hole/slot in the material could result in compromising the integrity of the sheet good because it could weaken where the strips are glued up.

There’s too much to talk about for me to put it all in this blog. Visit the Fab12 website, and look up Fab Foundation, Center for Bits and Atoms, and FabAcademy for more information on the wonderful things that are going on with the 1000+ FabLabs around the world.

|

|

Nowadays, we can all appreciate the chorus for re-shoring American manufacturing and hope that it may bring some jobs back to our communities. Yet there is an irony that, despite the wide recognition of our declining manufacturing base, proposals for manufacturing start-ups only grab attention when they are so compelling, so promising, that they can quickly scale to mass-production in China.

Nowadays, we can all appreciate the chorus for re-shoring American manufacturing and hope that it may bring some jobs back to our communities. Yet there is an irony that, despite the wide recognition of our declining manufacturing base, proposals for manufacturing start-ups only grab attention when they are so compelling, so promising, that they can quickly scale to mass-production in China.