When ShopBot began preparing for this year’s World Maker Faire in New York, we determined that we wanted to showcase how ShopBot CNC tools integrate into a small scale manufacturing process. Then it was time to get the creative juices flowing. In this case, it was the highly caffeinated creativity of Bill Young. Enter the initial idea: A lightweight food tray that one could place food on, contains an opening to hold a beverage, and can be held in one hand while using the other hand to eat and drink–and that could be made for the cost of a hot dog at a food truck event.

Bill cut a prototype, complete with a logo V-Carved into the surface, on his full-size ShopBot out of plywood and brought it to the ShopBot offices to show it off. The intent of the tray is to use it when people are eating outside in an environment with limited (or no) seating and table space. For example–if you were to visit a food truck or were having a picnic, you’d have an easier time with all of your food and drink with the tray instead of trying to juggle it with both hands, and figure out some awkward way to hold something while you took a sip from your cup or took a fork full of food.

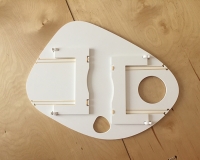

Bill Young’s initial tray design.

After a couple of us at ShopBot had an opportunity to hold the trays and get a sense of the comfort factor in holding it, there were some suggested changes and adjustments to experiment with on the next iteration of the tray. Should we make adjustments to the spot for the beverage? Do we need to add a support of some kind to keep the drink from falling through the hole if it’s of a smaller size? Should we add legs of some kind so that if one is sitting on he ground, they can put it down without it laying flat on the ground? What about a lighter weight material that is moisture resistant? Is the hole for your thumb to hold onto it in the right place and is it the right size?

Enter again, the creative mind of Bill Young and a new version of the tray. This time cut from sheets of expanded PVC, a material that is still reasonably lightweight, but also has durability. This latest version also had a removable support system/legs. Some more of us at ShopBot played around with the trays and looked at solving the securing of a drink if it’s smaller than the provided beverage hole. The use of a ponytail holder around a can of soda to stop slippage was experimented with (being that a lot of women/girls often have at least one of them on them or in their bag). What if we inserted a stretchable mesh or fabric to act as a sling for the drink? What if the legs of the tray folded up to make the tray flat again when not using them? While the group continued to brainstorm on this and other potential revisions to the design of the tray, we sought out some information from sources that could give us some genuine usability feedback: food truck owners.

Durham, being a particularly foodie town, has a wealth of resources when it comes to opinions on food related items. We took a few of the initial prototypes to someone that owns a high-end food truck that’s hired for special/private events such as wedding receptions, anniversary parties, corporate events, or graduation parties. Being an avid woodworker himself, he had an instant appreciation for the tray and its elegant simplicity. He also gave us a different perspective on uses of the tray. Being that there is limited space in the food truck, the trays would need to stack flat or up on a shelf so that they could easily be used, wiped clean, and stored again. He really liked the stand or “legs” but wanted something that was all one unit so he didn’t have to store pieces in different places on the truck and/or give instructions to customers on how to set it up. Being able to customize the trays for a special event, for a keepsake for the guests, is a win all day long. Being able to pre-produce trays that can then can be customized by VCarve engraving in small batches would give him a lot of flexibility.

We also shared the trays and stands with a friend of ShopBot who has a local industrial kitchen, along with numerous resources for food truck businesses, where food trucks use the kitchen to prepare their foods and that also contains a large event space. His reaction and ideas for the trays expanded further than what we’d discussed with others. To him, this was a great solution for being at the beach and needing a tray for snacks and drinks. He saw it as more of a “traveling” food tray that you’d keep in your car or with a lawn chair. That way it could be used at any event where a person would be hanging out for a while and need a place to set your food and drink down without it sitting directly on the ground. He also raised the concerns for making sure the tray wasn’t too heavy once loaded up with food and drink and wondered how a child or an older person might handle the tray, or how a disabled person might assemble and use it.

We returned from our local visits and feedback with a few new design challenges: could we add legs or a stand that would be out of the same material that would act as one unit and fold flat when not in use, use the ShopBot to manufacture the additional parts, and attempt to keep costs of production in check?

This is where ShopBot’s Brian Owen entered the arena and started working on an idea for the tray making use of foldable legs—so that a person can use the tray laying flat or open up the legs and use that added height when needed. He began experimenting with a system for the legs that didn’t consume a lot of additional material and could be assembled with additional parts that didn’t require specialty parts. What he came up with? A structure that involved some extra cuts into the tray (which, with a CNC, is a pretty easy task once built into the cut file), some small legs for the support structure, and rubber bands. Yes, rubber bands.

Not only did Brian’s adjustments work as legs to hold the tray, but with some additional minor adjustments, it also acted as a support underneath the tray for the drink in the beverage hole. We now had a product that incorporated the changes that made our food tray more multifunctional. Our next step was to see how well the tray functioned in an environment it was intended to be used in. This is where the employees at ShopBot got to be our beta testers—but also got fed a good meal and enjoyed being outside in the fresh air one late summer afternoon.

Using the CNC to cut all the parts for this tray was a huge success. It gave our design team a few restrictions that turned out to be key elements in the overall product design.

We’ve learned a lot along the way in the evolution of this project and it’s still evolving! Brian Owen has tweaked the design files to allow for faster and easier assembly, Bill Young continues to make tray variations, one dubbed the “winer” for a wine and cheese party (smaller tray, slot for wine glass stem), and we discovered that doing the VCarve engraving with a masking material applied first makes painting and finishing work much cleaner! With our project spec changes midway through this project, our cost per item did increase due to additional material used, cut time, labor, assembly, and overhead. So while we were looking to keep our cost per tray around that of a hot dog at a food truck event, we found it came in more around the cost of a cheeseburger, fries, and drink. Bill still hasn’t given up on the vision of the minimum viable product, “cost of a hot dog” version. We’ll be testing some of that one out at the Maker Dinner during the New York Maker Faire—everyone needs a place to hold their cup of beer while eating their plate of paella!

Stop by our booth at World Maker Faire in New York September 23-24. We’ll be showing the full production process in action.

Leave a Reply