syz·y·gy [siz-i-jee]

noun

Astronomy: An alignment of three celestial objects, such as the sun, the earth, and either the moon or a planet.

Any pair of connected or corresponding things.

For most people, the word “syzygy” seems like something out of a foreign language dictionary. Primarily used in astronomy, the term refers to the lining up of multiple objects in space. However, it also can refer to any pair of connected or corresponding things. For Keith Larrett, the word has an even deeper meaning: his wife used it in conversation one of their first dates, and it stuck with him. So much so, in fact, that he took it as the name of his Palm Coast, FL woodworking business, and he’s been producing some amazing built-in cabinetry and CNC furniture projects for both local and out-of-state clients.

A Built-In Client Base

Prior to going full-time with Syzygy, Keith spent over a decade installing cabinets in the Palm Coast area. In tackling all different kinds of installation situations, he became more and more interested in the design and brainstorming aspect of working with unique spaces rather than just hanging them, and eventually started doing some design on the side. Thankfully, the client base looking for design overlapped with those in need of installation, and after a while he found himself providing both.

As his client base grew from word-of-mouth and referrals, the possibility of full-time custom furniture became more of a possibility. Keith found himself becoming more and more involved with the planning, brainstorming, and design component of CNC furniture installation, which required more onsite measurements and working from pictures to figure out how things would work in unique spaces throughout homes and businesses. Eventually, he realized that with an upgrade in equipment, he’d be able to open up a whole new world of possibilities.

ShopBot and Cabinet Design

When looking for a tool that would allow for Syzygy to work full-time, it was very important that whatever he bought be compatible with eCabinets. Keith had gained some experience with the program over the course of the past several years, but he had some trouble finding a well-built tool that could withstand daily use and make the most out of the software. He was fully new to the idea of a CNC tool, but everyone he had spoken to had mentioned that it was a must for any woodworker’s shop. After asking around, the lone candidate was the ShopBot PRSalpha. He invested in a PRSalpha with 5′ x 8′ table with Automatic Tool Changer and immediately realized its importance to his business. Not only was it compatible with cabinet software, but it could handle sheet goods of every type, from MDF and plywood to plastic and acrylic.

One of Syzygy’s most recent installations, a built-in office desk.

“When I first bought my PRSalpha, I thought it would do everything for me,” says Larrett. “But what I’ve learned since is that it’s even more important than that: it doesn’t do the work for me, it allows me to do work that wasn’t possible before, and do it with more speed and precision.”

Unique Process for Unique Projects

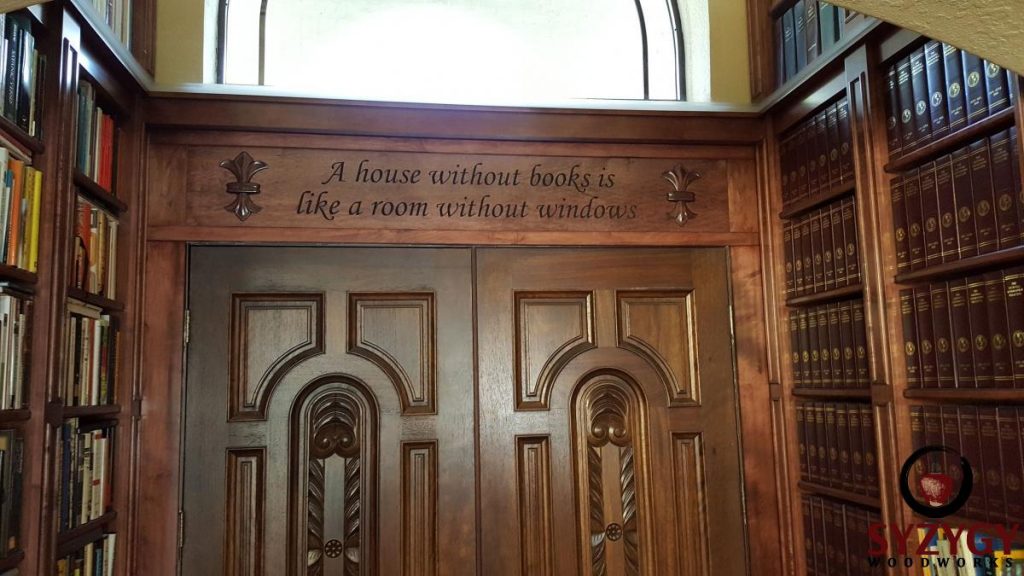

When it comes to difficult projects, Keith doesn’t shy away from trying new things: he often goes into a client’s space having little more than a vague idea of what they are looking for. In fact, his first client challenged to create a huge bookcase installation that filled a 20-foot high 4′ x 8′ foyer and had a layer of acrylic that one could actually walk out on! After going over to visit and take measurements, he entered his shop with a rough sketch, dimensions, and a few ideas.

Knowing that he could cut all of the parts and make adjustments on the ShopBot made things a little easier for Keith. He was able to machine the intricate designs needed for all of the detail work, including the Horace Mann quote that appeared on the header into the main home: “A house without books is like a room without windows.”

A job of this scope was something that Keith had never done before, but as he puts it, he “figured it out as he went”, since he was able to carefully engineer the entire installation just as if it was kitchen cabinetry: by making sure everything is properly mounted and built into the space, there’d be no worries that it would be done right. And any prototyping could be done on the ShopBot before it was officially installed.

Still, with all of his confidence and experience, it was his brief time as a professional skydiver that came in handy the most once installation was completed.

“I’m not going to lie,” laughs Keith. “That first step out onto the acrylic floor was kind of a ‘leap of faith’. But I’m confident that everything in that room is there to stay.”

Keith Larrett demonstrates the support of the clear acrylic floor.

Keeping the ShopBot Busy

Thanks to his great work, reputation, and huge fan response on social media, Keith has no problem finding work these days. As if running a full-time furniture business wasn’t enough, however, there are still times when the ShopBot isn’t being used. During these hours, while Keith draws up plans or uses the woodturner, he offers CNC routing services to his local Palm Coast community. This way, as Keith says, “the ShopBot stays as busy as I am”.

As one of Keith’s clients, I can attest that he not only does work of the highest quality, he is a profectionist and a joy to work with.