One of the fortunate coincidences for my trip to Austin was that Wayne Locke’s CNC User Group was the weekend before SxSWEdu and SxSWCreate. Wayne’s gatherings are, by far, the longest running gatherings of ShopBotters and others that are interested in all things CNC-related. This year, as always, it was held in his shop behind his house outside of Austin.

Wayne is a woodworker and furniture builder that specializes in church furnishings. Like many woodworkers he works by himself, which means he falls into one of two categories…very organized or total chaos. Fortunately Wayne falls into the first one!

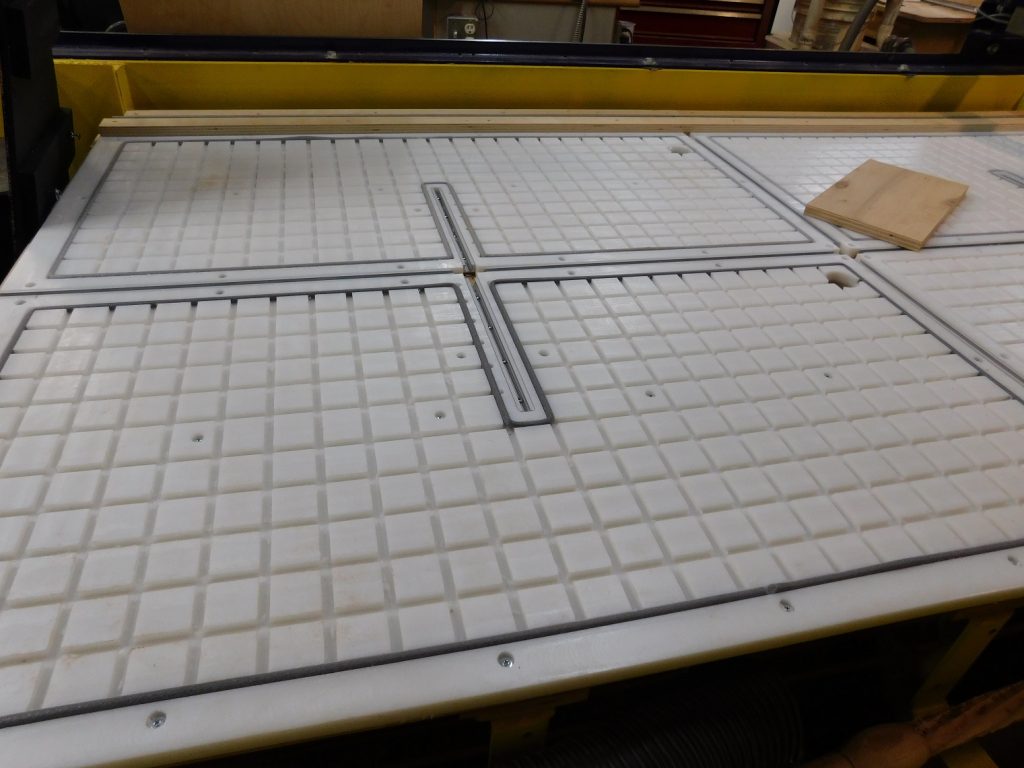

Since he does such a wide variety of work, Wayne’s PRT ShopBot has been modified with a couple of custom additions. He’s added an indexer to the side of his ShopBot, modifying the table so that he can do an 8′ turning. He’s also added a very versatile vacuum hold-down system with a highly customizable plenum for holding parts of all sizes. His table is a funny color, but we try not to hold that against him.

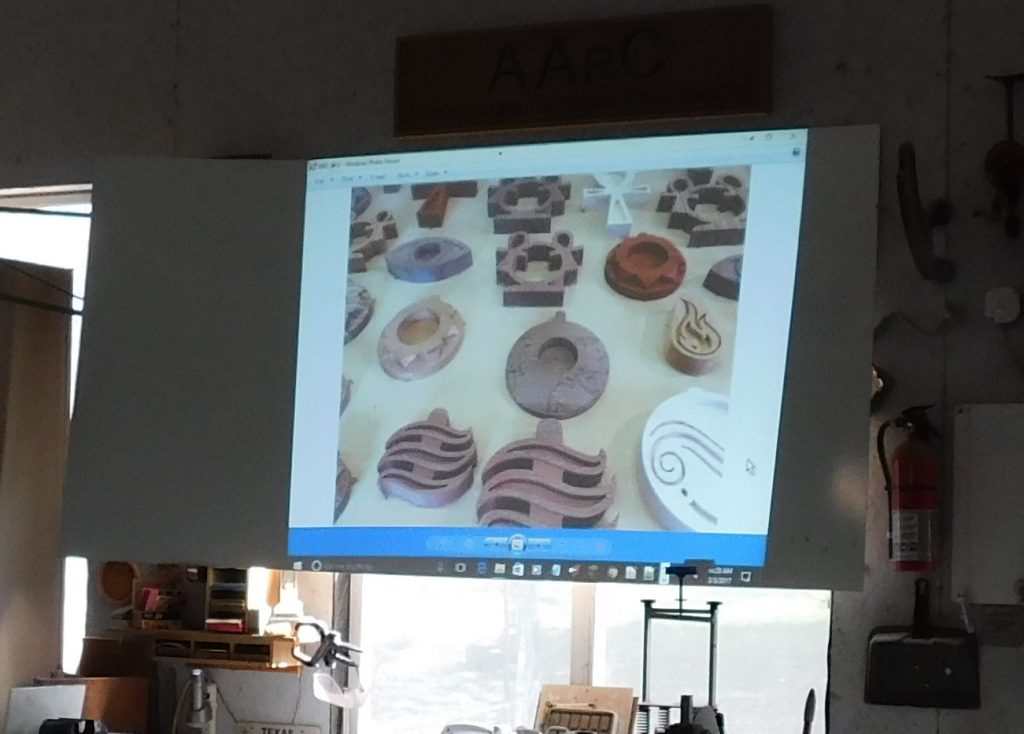

One of the first presenters was long-time ShopBotter Santiago Laverde. Santiago does custom cutting and specializes in jigging and setting up for production runs. He started with an overview of some of the work he had done, followed with one in jigging for production that used a bottle opener as the example product

One of the main topics of discussion this year was chairs, which began with a presentation by Gary Weeks that described how they currently make their rockers. Their handmade rockers are beautiful, but very labor intensive to make, so they came to the User Group to explore the idea of adding a ShopBot to their shop. Lots of creative and clever thoughts from the crowd, including a discussion of what “handmade” really means and where tools of all kinds fit in. It’ll be interesting to see what they decide!

Longtime ShopBotter and frequent forum participant Steve Glassell followed with a great presentation on how he uses his ShopBot to build his line of rustic chairs. Steve has developed a very clever joinery system that makes assembling his chairs quick and strong, held only with glue and a single screw. Steve has created this design–and the files–so that everything is cut from one side only, without any material flips. He and Wayne followed up with a two-way discussion of the ways they shape their chair seats.

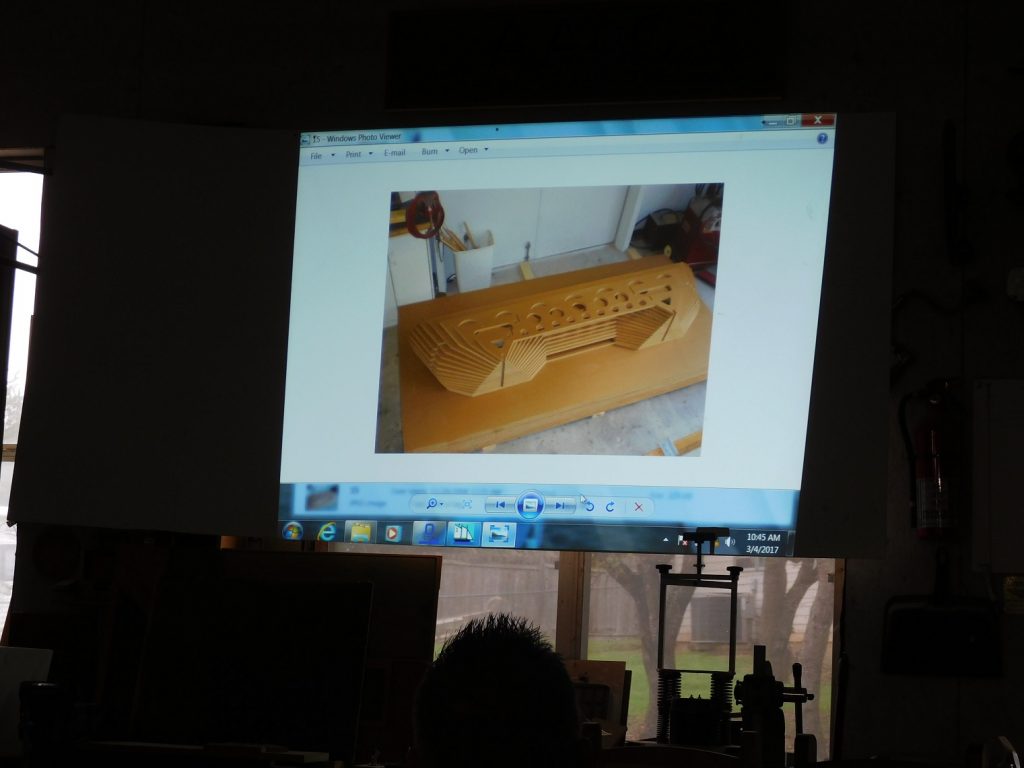

Texas Boatbuilder David Lemke talked about how he used his ShopBot to build both boats and “plugs” that production boatbuilders use to make molds to manufacture boats. As a plus, he brought signs for a of couple of attendees to take home.

Brett Dickinson, long-time ShopBotter and Texas educator, talked about some of his projects and the schools he’s worked with including the Dripping Springs, Texas Fab Lab and their F1 in Schools team.

Machinist Matt Schreiner, also of Dripping Springs, spoke about his spreadsheet system for fine-tuning feeds and speeds for machining materials like aluminum. He also showed some of the techniques for aluminum machining techniques that he uses on his XCarve using Fusion 360.

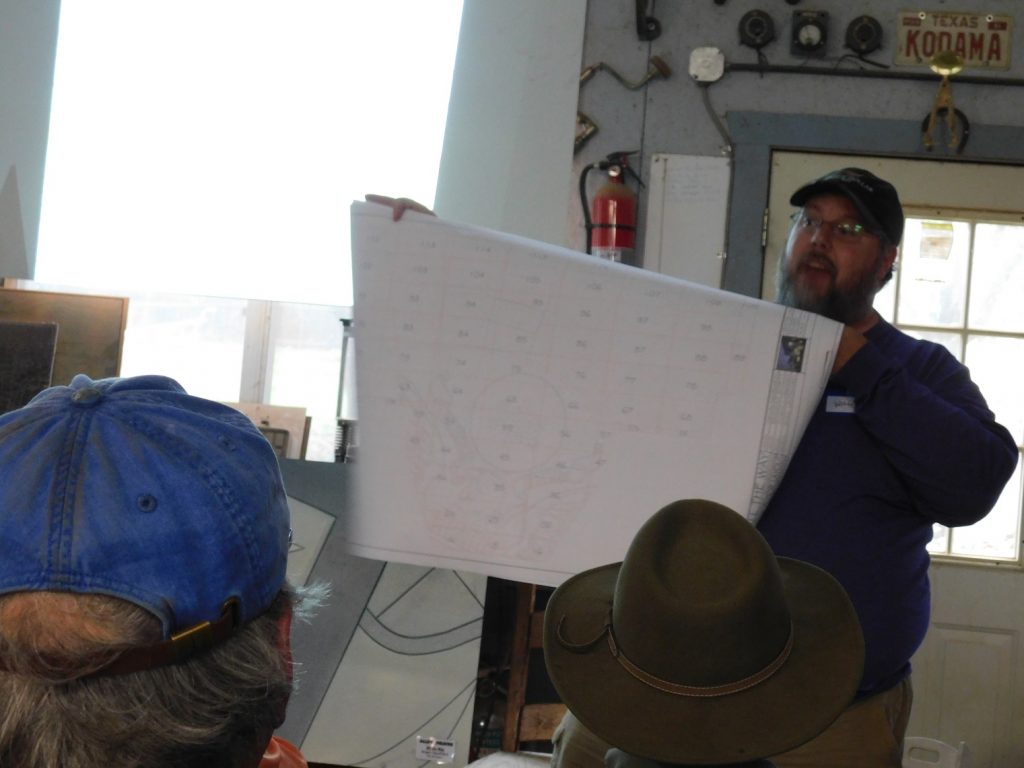

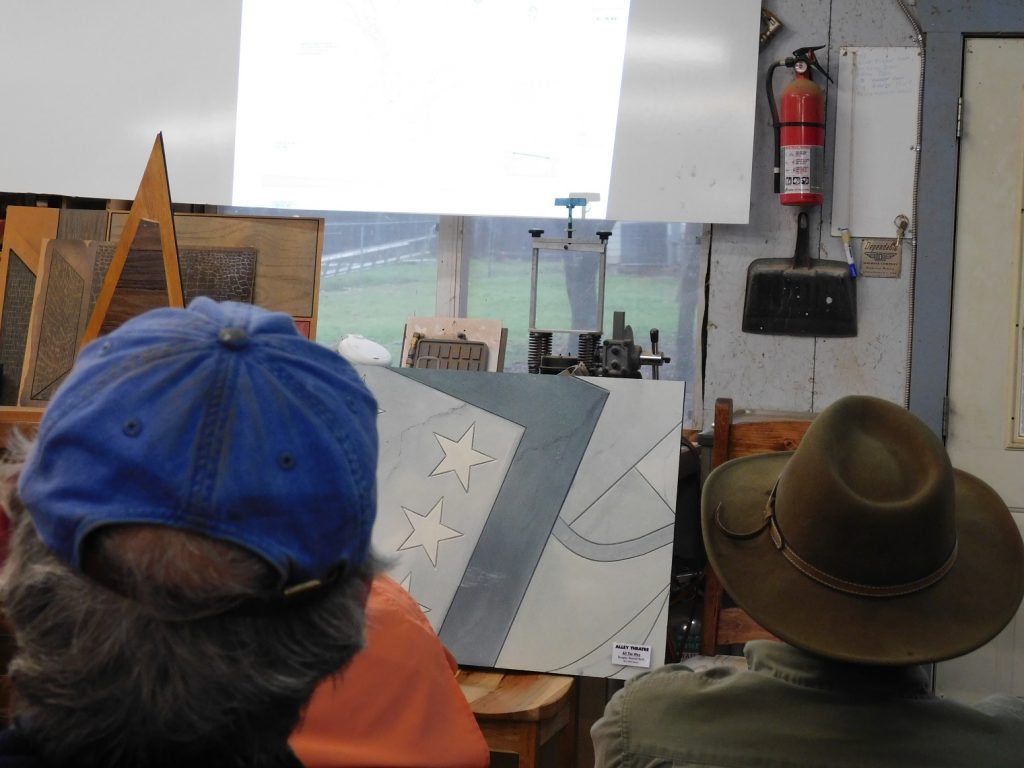

Will Leonard of the Alley Theater in Houston wrapped up the event with a presentation on how he uses their ShopBot to make sets for the productions that the theater does. Will uses their ShopBot to cut out the pieces and also to engrave lines for color changes, to make it easier for the painters to get a clean edge. Although much of the design and fabrication is digital, they still need paper plans to keep track of it all!

The most important part of any ShopBot event is the show-and-tell items and conversations that are constantly going in. And of course lots of food!

My next stop is a visit with Ken Picou, an amazingly creative woodworker and ShopBotter that has been to Wayne’s gatherings for years. Stay tuned!