The tastiness of making mistakes.

In the 52 years that the New York State Technology and Engineering Educators Association (NYSTEEA) has been meeting, there have been a lot of changes in the design software and equipment available to teachers and students. Schools have been adding digital fabrication equipment, including CNC, into their classroom and pursuing a hands-on teaching model.

ShopBot Tools attended this year’s 2-day BSTEM event in Malta, NY, which included sessions on everything from elementary robotics to model railroading as a STEAM activity. During the mornings and breaks throughout the day, educators had a chance to see a Handibot in action, as well as understand the workflow that aligns closely with what they are teaching day-to-day in the classroom.

ShopBot Tools sponsored the Awards Dinner, held at the Automobile Museum in Saratoga Springs. In a brainstorming session a few weeks before the event, Sallye Coyle and I decided to create a gift for each attendee. Sallye has been playing with using ShopBots to create molds and models for casting materials such as aluminum and glass. Why not demonstrate ShopBot’s capability to machine in 3D by creating small molds to cast chocolate for an end-of-meal treat? We had no idea what we were getting into.

The ingredients for our experiment required different types of chocolate and mold release sprays.

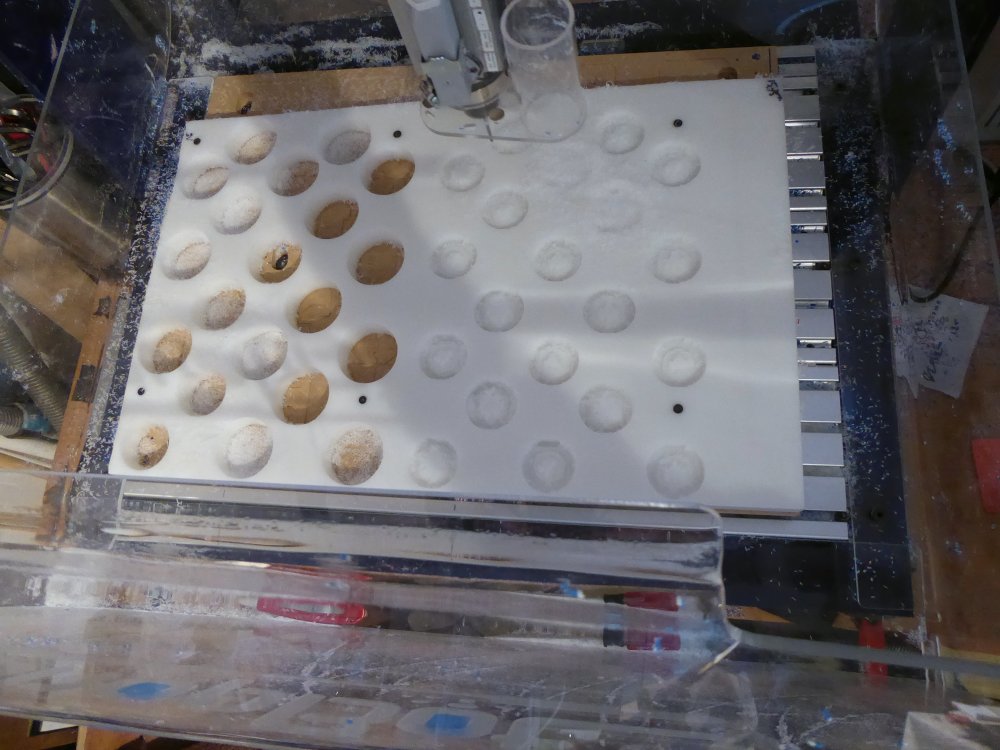

The first step was to prototype the mold (negative space) that we would pour the melted chocolate into. Since we intended for people to eat the chocolate, we started with food-grade HDPE, the solid material that plastic cutting boards are made out of. It machined beautifully, and the melted chocolate flowed into the mold without any problems. However, after it solidified again, both kinds of chocolate we tried were too brittle to release easily from the rigid mold, even with a mold release agent. Hardship prevailed: we had to eat all the chocolate that broke as it was removed from the prototype molds.

The next step was to create a model (positive space) that resembled the actual shape the chocolate would take. Then, a two-part food-grade silicon material was poured around the model so it would become the mold. The silicon remains flexible after it sets, so a brittle material can be popped out. In the first tries, we tested two types of mold release: PAM and coconut oil. The finished product came right out of the mold with both, but the top of the chocolate was discolored with unappealing white streaks. When no mold release was applied, the chocolate still came out of the mold easily and retained its rich, dark color.

Silicon molds were successful in producing chocolate shapes, but the mold release left discoloration.

We now had a functional mold, but our prototyping showed us another problem with going into small scale production: the two-part silicon mold material was just too expensive and the process itself too time-consuming for us to make 150 molds. While a flexible material such as gelatin came out of the rigid molds, it just was not as appealing as chocolate. So, we came up with other options for the giveaway that included ShopBot-cut rack and pinion gears, which also explained how the tools are made.

The project didn’t turn out the way we had initially hoped. However, the prototyping process was a great example of many things that engineering teachers are trying to convey to their students: design thinking, learning from failure, iteration, record keeping, and decision making. Cost effectiveness is another important consideration that needs to be put into the equation.

Sallye used Aspire, a 3D design and machining software, to design her molds and models. Aspire is the “big sister” to VCarve Pro, the 2D CAD and 2D/3D CAM software that comes bundled with every ShopBot and Handibot. She machined the prototypes and did small scale production of the molds, models, and gifts on a ShopBot Desktop.

The day after the dinner, several teachers came up to thank ShopBot and reveal how the evening’s talk had inspired them. One teacher said that, in 27 years of coming to the NYSTEEA conference, no one had ever talked about food. He had a grant to create a garden to engage kids who would not otherwise be drawn into science and engineering. Others learned that 3D models can be realized in more ways than with 3D printers, and that it is important to have a suite of digital fabrication tools available, including a ShopBot or Handibot CNC. Having the right tools in the classroom/lab allows students to follow through on their ideas from CAD design to mock-up to tangible item, and to learn from their mistakes and revise. In fact, it is the mistakes that can lead to some of the greatest successes.