School’s out but lots of things are going on with my students over the summer… One of the things we are working on with our ShopBot Desktop is fabricating about a dozen award plaques to give to exemplary delegates at Sewanhaka High School’s Model UN Conference next year. We wanted to decorate each plaque with a small judge’s type of gavel that “MUNers” often use in their meetings and decided to try to carve it out of acrylic.

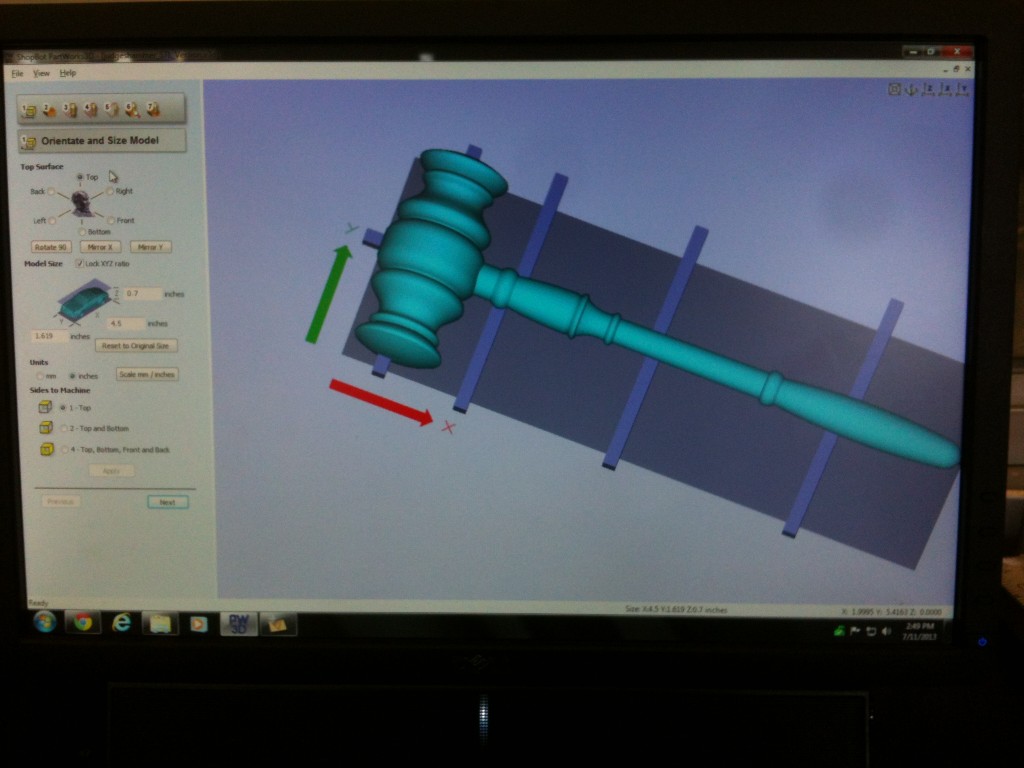

We started with an STL file we found online and sized it to fit the 0.5″ thick acrylic sheet we have available.

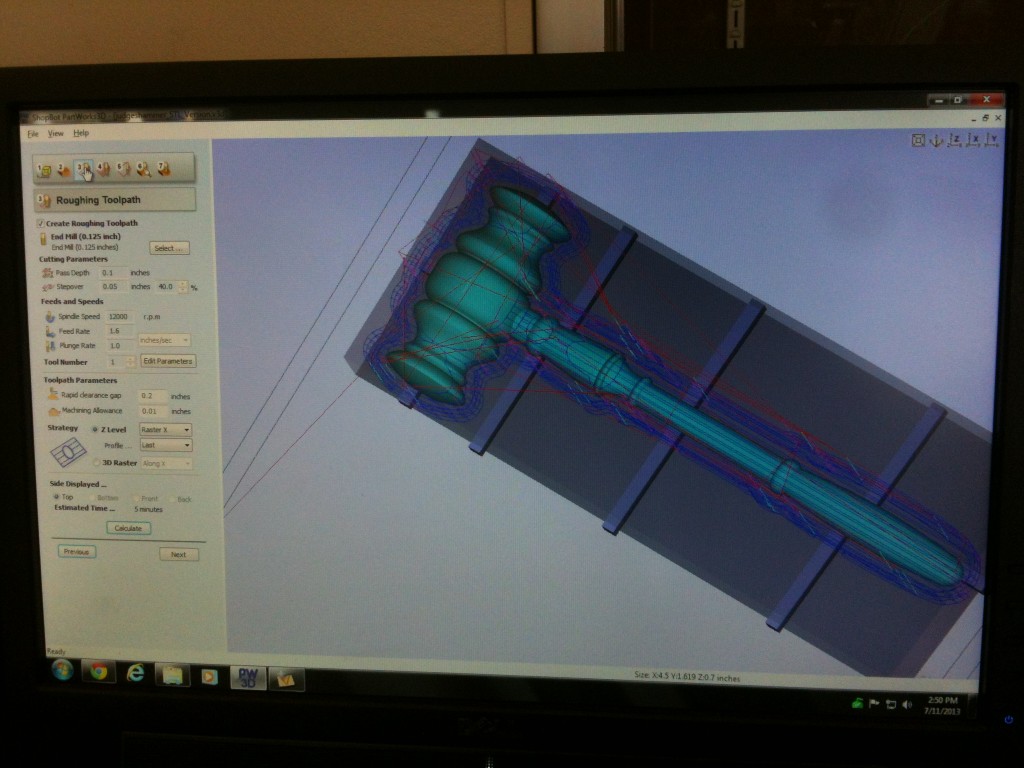

We realized that we could save time and increase the size of the finished part by carving only the top half of the model since we will be mounting the gavel flat against the plaque. Here’s what our z-level roughing strategy looked like…

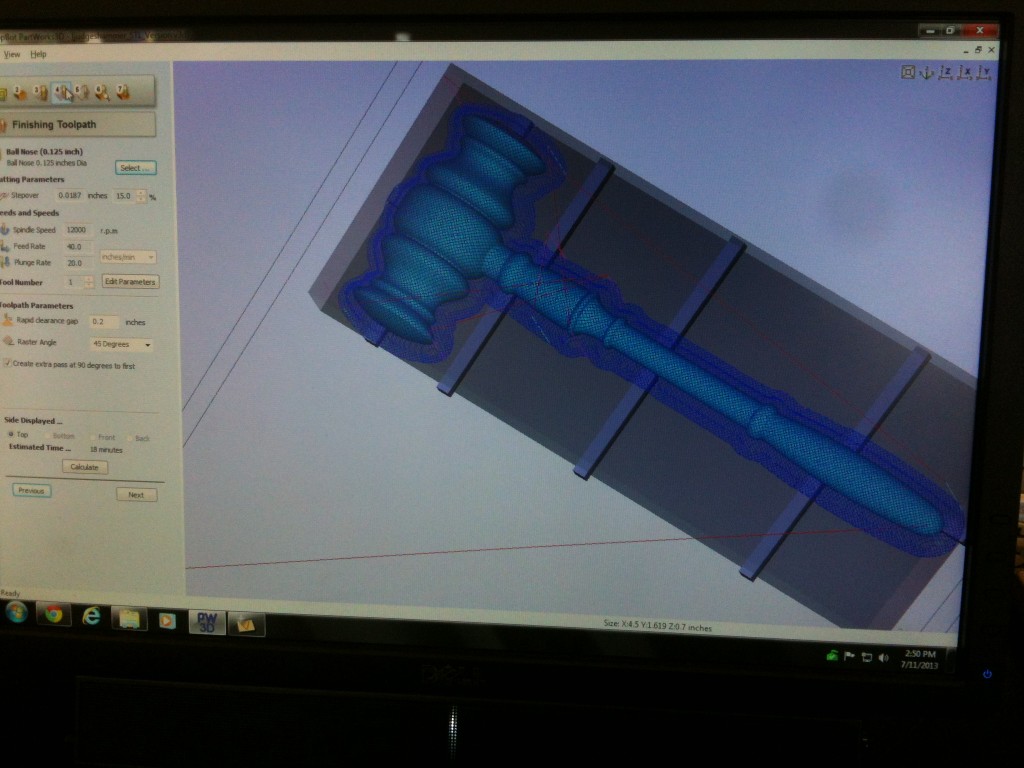

And our finishing pass calculations…

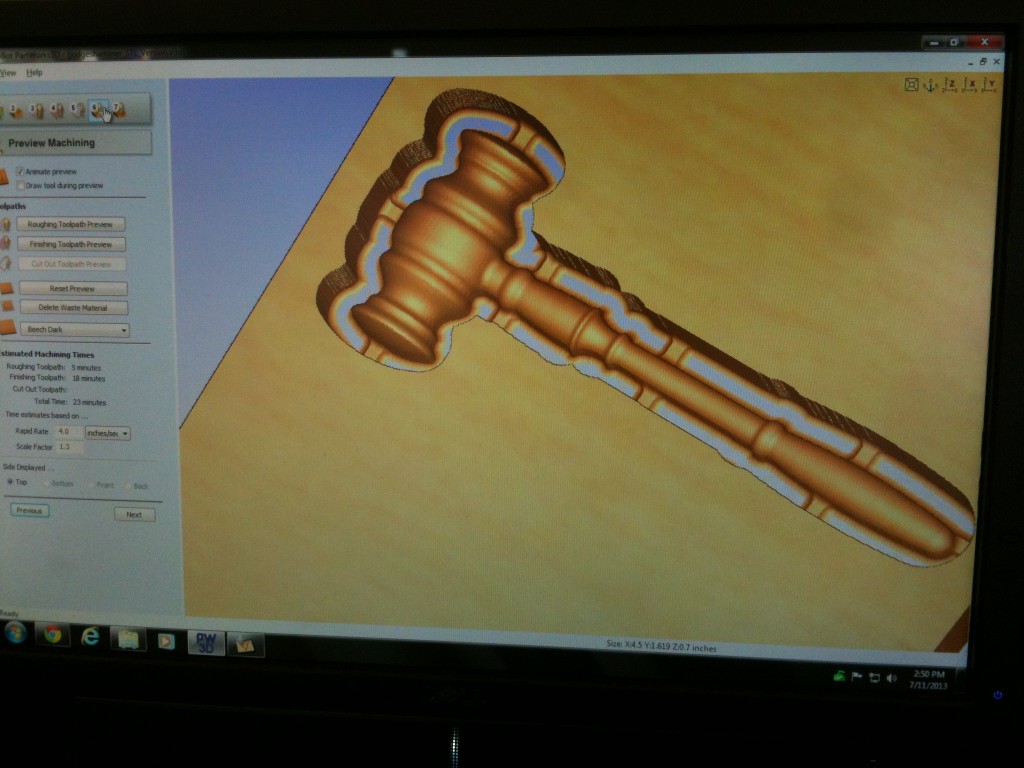

Simulation in PartsWorks 3D showing the location of tabs…

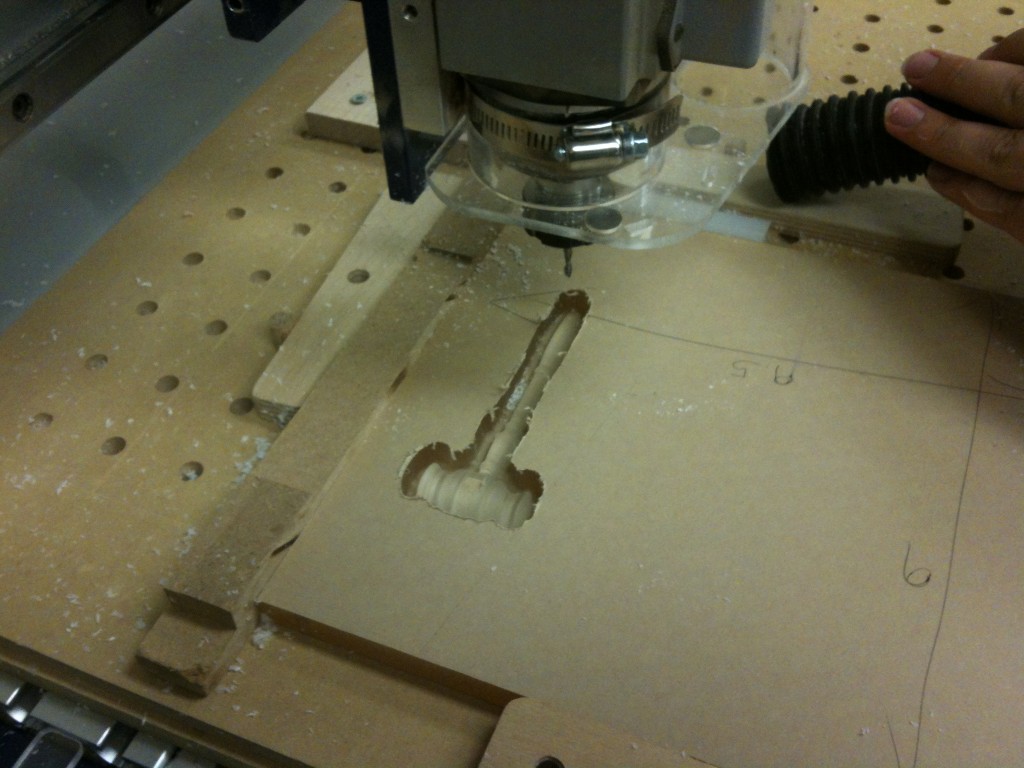

Roughing went smoothly using a 0.125″ double-fluted end-mill at 13,000 RPM (96 IPM). We were satisfied with material removal but paused to vacuum up chips in-between roughing passes to avoid re-welding material… We finished using a 0.125″ ball end-mill at 13,000 RPM (40 IPM) and added a second pass at 90-degrees to the first pass to get a smoother surface.

A closer look…

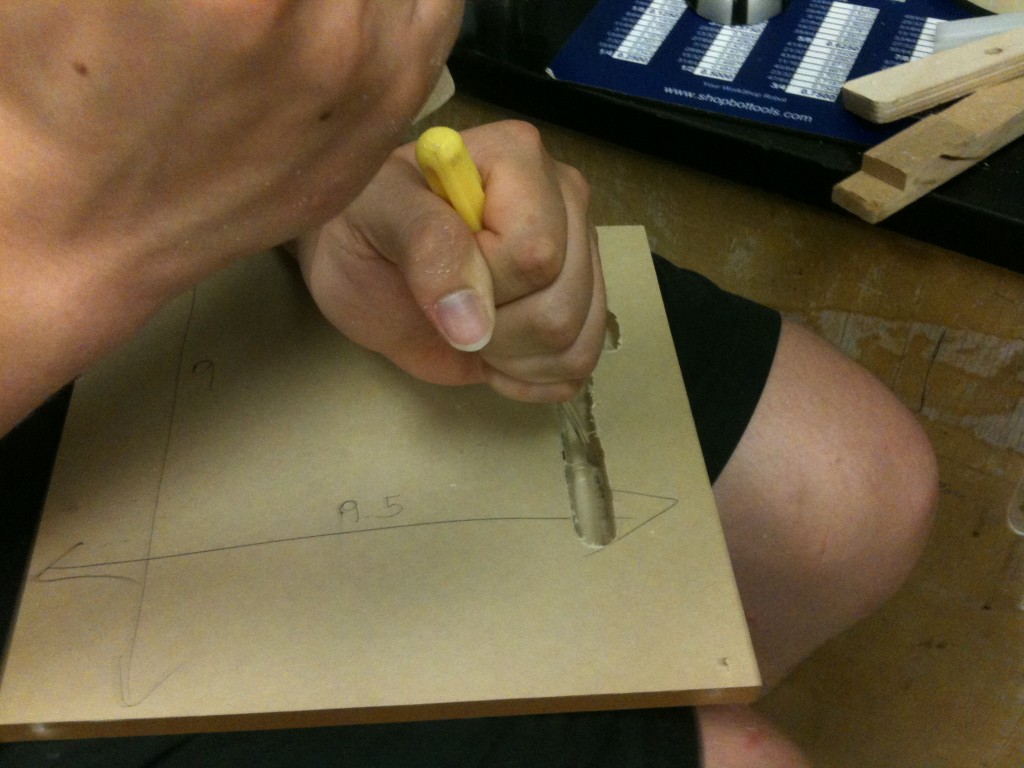

Unfortunately, after releasing the workpiece from our hold-down system, we realized that we had a slight set-up error in the z-axis that left too much material around the model break it free easily…Oops! (We ended up chiseling it out)

Even so…the gavel looked really nice after it was freed from the acrylic plate and it gave us a good idea of what we could produce.

Not bad for a first try…we’ll set-up a second run in the next few days and nest more pieces into our acrylic sheet so that we can use the rest of the panel efficiently.

What kind of projects are you working on this summer with your ShopBot?

All the best,

Jack

Leave a Reply