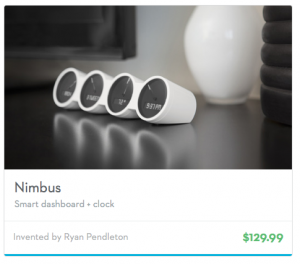

In the last months of 2013, as Santa’s helpers hurriedly made presents, the elves at Quirky’s headquarters in NYC were hard at work bringing new gift ideas to market. One of them is the Nimbus, a highly customizable 4-dial dashboard that tracks what’s important to you. According to Quirky’s site, you can “personalize each gauge using your mobile device to keep an array of info up-to-date and available at a glance. Nimbus can monitor your commute traffic, weather, email, calendar, social media networks, and more.”

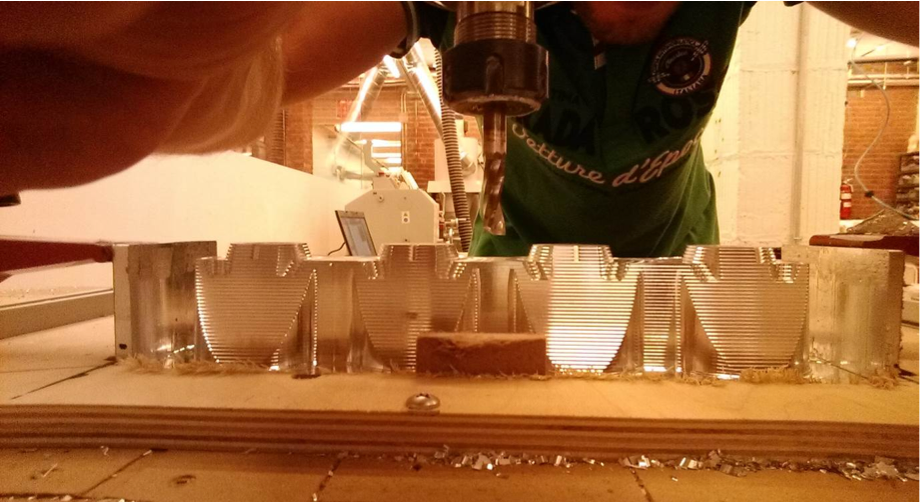

Designed to be made with a plastic housing, Quirky’s product designers were hard at work readying a limited-edition, brushed aluminum Nimbus — and that’s where their ShopBot Buddy, with industrial spindle and 12″ Z-axis came into play.

Designed to be made with a plastic housing, Quirky’s product designers were hard at work readying a limited-edition, brushed aluminum Nimbus — and that’s where their ShopBot Buddy, with industrial spindle and 12″ Z-axis came into play.

But hang on, what is Quirky anyway? And how does it work?

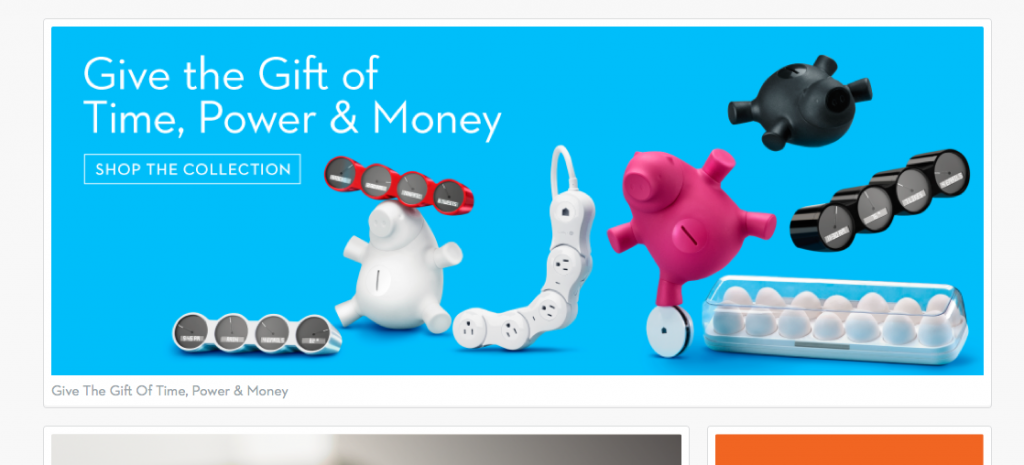

Quirky has re-invented the process of bringing new products to market. Rather than taking the “old school” route of expensive market research, new product ideas are submitted by and ranked by the biggest market there is: the Crowd.

People are invited to submit their ideas, anything from half-baked notions on napkin drawings to fully baked ideas, to Quirky’s site for voting by the crowd. The most popular ideas are put into consideration for development into products for market. But participation doesn’t end here. People can get involved voting on the product’s colors, submitting names and more, and at each step of the way participation earns you points that turn into dollars when the product succeeds.

In this short video, Quirky’s Founder and CEO Ben Kaufman describes the lively interactive process of how a product gets chosen to bring to market:

Case-in-point: The Nimbus

That’s the Nimbus, below, balancing on top of the piggy bank.

The originator of the idea is Ryan Pendleton of Grand Rapids, Michigan. A self-proclaimed geek as well as photographer, gamer and journalist, Ryan’s initial inspiration for Nimbus was an app-enabled alarm clock, but it became so much more than that. Ryan saw an opportunity to have a bigger impact on peoples’ daily lives by incorporating diverse streams of information. Thus, Nimbus became a personal dashboard.

Ryan Pendleton, the guy with the idea for the Nimbus. So far he’s earned $35,946, and the Quirky Community (the crowd) has earned $43,005.

Prototyping the Nimbus

According to Quirky Product Designer Richard Ganas, Quirky’s ShopBot Buddy has played a critical role in the development process.

“We’ve had numerous 3D printers and other digital tools in our production studio for awhile, but our need to mill in aluminum, as well as to work with larger prototypes, has made the ShopBot Buddy invaluable,” says Ganas.

In addition to the plastic-housed version of the Nimbus, Quirky was working on preparing a limited-edition (a thousand or so) run of the Nimbus to be housed in brushed aluminum. Quirky had identified a local vendor to handle the limited run, but to test and refine the design in aluminum required milling work with the ShopBot.

Richard describes how Quirky employs its Shopbot:

“We currently use our ShopBot Buddy for milling in Renshape foam and aluminum. We use the Shopbot primarily for 3D milling, and because we want the ability to prototype larger objects, we chose to have a 12″ Z-axis on the tool. We have also used the Buddy to mill out molds for thermo-forming and casting.”

In the case of the Nimbus, the team first used Solidworks and 3D printing processes to play with different shapes for the product. Further along in the process the production team used the ShopBot and Renshape foam to help them determine the number and type of different tools they’ll need to ultimately produce the consumer product.

As they prepped the limited run in aluminum, the team made use of the ShopBot to help them make decisions regarding the final finish of the product, polished vs. brushed aluminum.

The unique value of the ShopBot to Quirky.

Rich Ganas explained, “Whenever we need to work with a larger product, the ShopBot is a great tool for us. For example, we’re working on a product in the shape of a helmet. For us to 3D-print a prototype would easily take 20 hours, whereas using the ShopBot and Renshape is much quicker. It enabled us to mill a few hundred helmets in foam and get them onto the heads of testers. And again, due to the size of the helmet, the Z-axis did the trick for us. Altogether, the Buddy is a fast, precise prototpying tool for us.”

Rich noted that he came to this tool with little background in CNC, but found he integrated the ShopBot into his process quite quickly. He noted that ShopBot’s forum has been very useful, and with any technical support issues, ShopBot’s team has been very responsive.

For a quick and interesting view into Quirky’s production studio, take a look at this video:

Want to learn more about the ShopBot Buddy? Click here.

To get in touch with ShopBot, call 888-680-4466 or use this contact form.

Really interesting article and rather apt – never heard of them before but I’m happy that I now have. Great business idea and model!

Jon