Alibre Design is a full featured CAD “Design” program that creates 3D watertight solid models from which you can create Drawings and other output such as 2D DXF files in order to manufacture parts with CNC equipment. Alibre includes a full range of design modeling capabilities and does not require the user to write custom code or purchase utilities in order to accomplish standard design tasks.

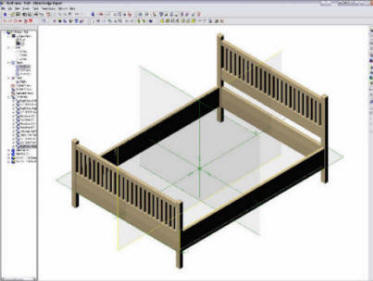

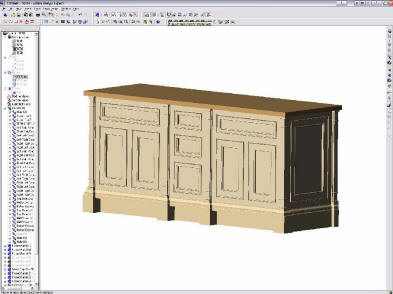

Designing with Alibre uses techniques very similar to those used in the manufacture of a piece. This provides a good opportunity to work through production issues while still in the design stage. We find it so close in technique to the woodworking process that we often consider our design process as Virtual Woodworking.

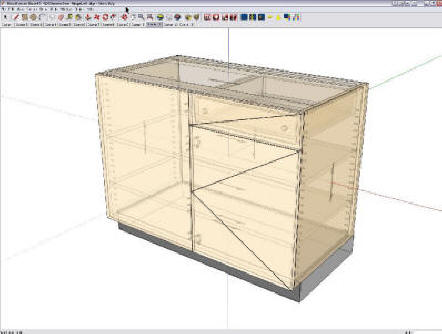

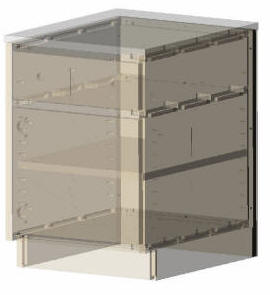

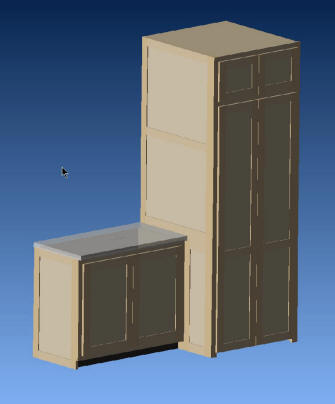

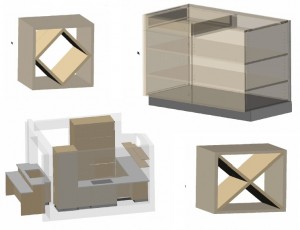

The solid nature of the modeled parts allows interference checking between parts and troubleshooting of the entire design before manufacture. A true graphical representation of the design and all the individual parts allows a thorough review of the component parts and the completed assembly.

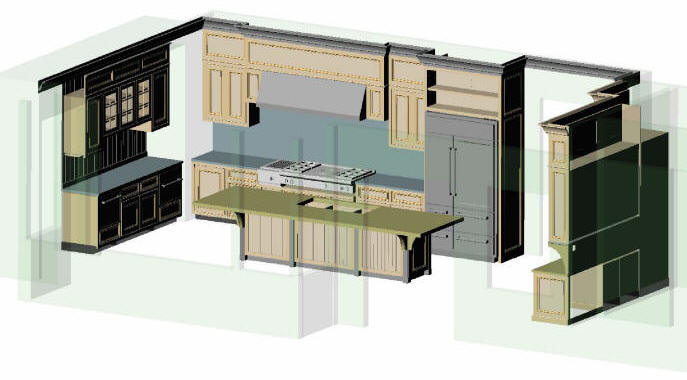

Alibre provides a SketchUp exporter add-on that allows you to export your Alibre designs into SketchUp, where you can do Room Layouts, Renderings, Animations, and Walkthroughs. Alibre Design can model almost anything you can conceive, and can be used to do custom designs of furniture as well as cabinetry. No need to wait for a programmer to add new capabilities to your design software, just create a 3D model of your design elements and combine them to construct your latest vision.

Constraints add a whole new design environment where you can easily specify that lines remain parallel or perpendicular, no matter the changes in design dimensions. No more graphical layout to make sure curves meet at a tangency, just select the Tangent Constraint and curves and lines are automatically constructed to meet with a smooth tangent transition. You can constrain design elements to meet at midpoints, remain concentric, and maintain many defined associations. Constraints don’t just define how geometry is originally created, but maintain their conditions throughout subsequent changes and modifications to the design!

Parametric Dimensioning allows designs to be driven by user specified dimensions, including user defined equations with common math operations. Dimensions are created to define the length of a line, not just report the length of the line you have already drawn. Dimensions drive the geometry and define the size of lines, circles, arcs, and other elements of the design. If you want to change the diameter of a circle, you modify the dimension associated with the circle rather than redraw or modify the circle.

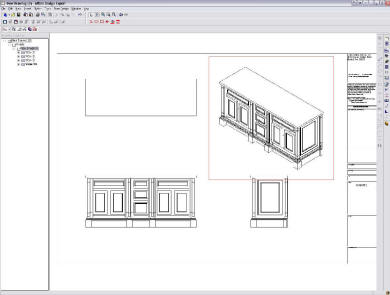

With Alibre you are able to generate complete drawings from your model with such built in automatic capabilities such as sectioning, detail views, projections, and a full range of standard drawing capabilities. You can do drawings with even the free Alibre Xpress version, and export those drawings to formats such as 2D DXF for manufacturing without spending a dime.

(image used with permission of Cullen Grace Joinery)

Drawings are created from the 3D solid model and are fully associative to that model. Change the underlying model, and the drawings will update to reflect those changes. Copy your design, change the dimensions and you have a fully completed and documented variation on your original design as all the copied drawings will update to reflect the changes to the model. Need to make similar parts of varying dimensions? Just make changes to the model, open a drawing that you originally made at 1:1 scale and export a new 2D DXF of that part. You have what you need to base the manufacture of another variation on the original part. Do a manual nesting of parts within Alibre and you can export a 2D DXF of nested parts ready to be toolpathed for manufacture. Have nesting software, you can import the 2D DXF files exported from Alibre and start cutting.

(image used with permission of Cullen Grace Joinery)

Alibre provides a user customizable Bill of Material or Cutlist capability which includes part dimensions you have defined in your model. While the free Xpress version does not include the customizable BOM capability, you can create a Bill of Material by using our downloadable template file. A Bill of Material can then be exported to a .csv file which can be imported into other software such as a Spreadsheet for further processing. We normally use only one standard BOM template and post process the exported .csv data to suit the destination program with scripts we have written in the free AutoHotKey scripting language. Those scripts are available for download, as well as our standard BOM template.

Alibre provides a user customizable Bill of Material or Cutlist capability which includes part dimensions you have defined in your model. While the free Xpress version does not include the customizable BOM capability, you can create a Bill of Material by using our downloadable template file. A Bill of Material can then be exported to a .csv file which can be imported into other software such as a Spreadsheet for further processing. We normally use only one standard BOM template and post process the exported .csv data to suit the destination program with scripts we have written in the free AutoHotKey scripting language. Those scripts are available for download, as well as our standard BOM template.

What is Alibre?:

Alibre Design is an affordable History Based Solid Parametric Solid Modeling program, similar to SolidWorks and AutoDesk Inventor (as well as a host of other expensive design programs). What differentiates Alibre Design is that it provides the essential capabilities of more expensive design programs at a cost that is affordable to the woodworker.

Alibre Design was created for the Mechanical Design market, but is ideally suited for the woodworker. As with most software vendors, Alibre provides instruction on how to use the features of their software (and free training videos). What they do not provide is how to use those features to create designs for woodworking. We have tried to remedy this situation by publishing training material at our website and the “Instructables” website on how to apply Alibre Design to woodworking designs. The Alibre Design Tips column for Cadalyst magazine is another good source for basic use instructions:

(Table rendering used with permission of Ian Kirby)

Alibre Design is NOT a Drafting software as the drawing capability are intended to be based on a solid model construction. The drafting tools are incomplete and relatively difficult to use to create a 2D drawing from scratch. To do so will only result in frustration and disappointment. Even for a simple rectangular part, it should be modeled as a solid and then a drawing created based on that part. The drawing tools are based on such use, and are quite powerful in providing documentation in this manner.

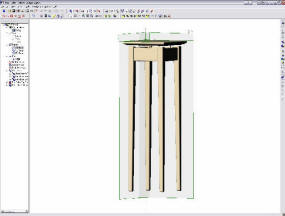

Alibre Design is of a class called a “History Based” modeler. The design is composed of a history of operations or creation of “features”. As with woodworking, you would cut a board to size before milling an edge or drilling holes. In Alibre you would first create the outline of the board and then create the edge milling and hole features. Unlike woodworking, if you accomplish an operation out of order, you can re-order the “features” in Alibre to correct your mistake.

The free Alibre Xpress version has a part count limitation, but exporting your design to SketchUp allows entire rooms to be created using only software available for free. We create an accurately dimensioned Site in Alibre and populate it with our designs for an Installation model. From that we create the dimensioned Shops drawings for customer review and approval. Fitting cabinets and furniture in an accurate model of the Site helps eliminate interferences and has greatly improved final installation of a completed project. We refine the site model as construction progresses to maintain accurate dimensions and troubleshoot installation difficulties.

Alibre Design allows us to create a virtual model of an entire project from which we can determine construction details, allowable dimensions, pleasing proportions, and evaluate possible problems before we even cut the first board. It has made the projects on which Alibre has been used to proceed smoother and with less waste than those done previously with 2D drafting software.

What we hope to accomplish with this column is to share our experience with Alibre Design and show how to use Alibre to efficiently and effectively model woodworking projects of all kinds. Visit the Alibre Design website and download your free copy of Alibre Xpress and begin modeling your woodworking designs today.

NEXT: From Part to Production