CMA 20th Anniversary Conference March 1-2, 2018 Denver, CO

ShopBot recently attended the CMA’s 20th Anniversary Conference in Denver, CO. We participated by sponsoring a lunch highlighting our 20+ years supporting small and medium sized cabinet operations with affordable and innovative CNC tools. Many of ShopBot’s first customers were cabinet makers and it was fun to touch base with some of the friends we made in our early years.

While a few of those customers have moved on to big-iron CNC’s, many others still depend on their ShopBot tools for day-in, day-out production; and many have added a second tool to increase throughput while creating agility in how they put their CNC equipment to use. Sometimes two tools are better than one, especially if they are affordable.

We also got to chat with newer customers at the event. More than ever, we find that ShopBot has the products and services relevant to the dynamic needs of today’s cabinet makers—who must be responsive to the changing needs of their markets. They appreciate tools that can adapt with them to accommodate what the new work demands. The ease of use of ShopBot tools, as well as their adaptability, configurability, and programmability, make them well–suited for the production methods of creative cabinet making.

Because we not only design and build our tools, but also develop our own highly usable software, we are well–qualified to help with a broad range of needs for those using CNCs in production. Our staff of experienced CNC users, developers, and engineers can work directly with customers on what options are best for their needs because we are the developers of the products we sell. And we use them in our own manufacturing, every day.

ShopBot’s CEO and Founder, Ted Hall, says “… being competitive today is about cabinet makers making effective use of smart technology. Just because a tool is controlled by a computer, or has a decal that says “smart,” does not mean that it will make you smart. You need a tool that is intuitive and interactive … a tool that puts you in control of your work and production. We’ve put a lot of years into making equipment that works with people.”

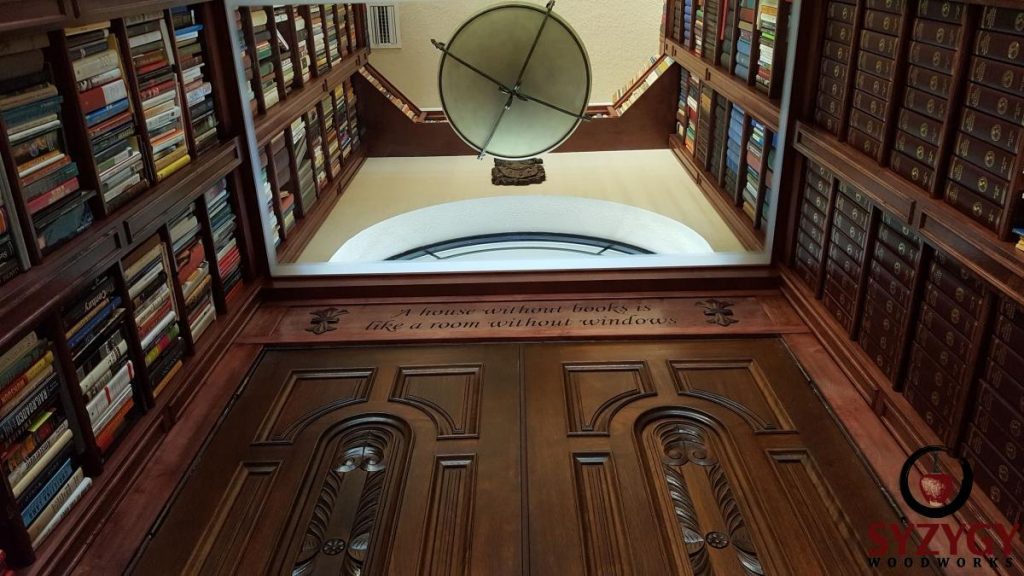

“When I first bought my PRSalpha ShopBot, I thought it would do everything for me,” says cabinet maker Keith Larrett. “But what I’ve learned since is that it’s even more important than that: it doesn’t do the work for me, it allows me to do work that wasn’t possible before, and do it with more speed and precision.”

Keith Larrett, Syzygy Woodworks

2014 PRSalpha 5×8 with Automatic Tool Changer

ShopBot Spotlight: Syzygy Woodworks

“I needed to find a CNC that could be assembled in my workspace and one that didn’t break the bank. I was a bit surprised with sticker shock for the caliber machine I wanted to get into – and even then, these machines couldn’t be disassembled. That’s when I stumbled across ShopBot Tools. Their machines had an excellent reputation and their customer service was out of this world great,” says custom closet and cabinet maker Andy Glass. “I was a bit nervous on what add-ons might bring the cost up to and I was extremely relieved to see the final price. It was so much lower than the competition that I decided to add-on a service tech to come help me set it up, tune the machine, and train me on the software and ATC capabilities. It was an extra cost, but even with that addition it was well below the competition; and bringing the field tech to the shop was the best decision ever.“

Andy Glass, Glass Impressions

2017 PRSalpha 5×8 with Automatic Tool Changer

Andy Glass Knows How to Make a Good Impression

“The ShopBot has met and exceeded expectations. We’re able to perform repetitive tasks such as making the parts of tables, chairs, benches, and cabinetry much faster than before — so of course it saves us money. And there are some areas where CNC has afforded other benefits. For instance, I knew that we could do decorative carvings using the tool, but hadn’t really intended to do much of this work. Well, I’ve found that I’m doing more and more of it, because clients are really liking the work.”

Andrew Coholic, Joe Coholic Custom Furniture, Ltd.

2012 48″ PRSalpha ShopBot Buddy® with Industrial Spindle and 4-foot Powerstick

Custom Furniture Maker Finds Surprising Benefits of CNC

ShopBot has made CNC accessible to small and medium sized shops. We don’t just import and resell something we don’t understand. At ShopBot, we design, develop, build, and support our tools, all from our Durham, NC facility. Our customers know that we know CNC—and that we know cabinet making—inside and out. Give us a call, visit our website www.shopbottools.com, or better yet, join us for one of our interesting, useful (and fun!) trainings at our headquarters in Durham, NC. If you can’t get out to North Carolina, keep your eye on our schedule of events and plan to attend one of our regional events where you can learn more about how we’ve helped cabinet makers compete and thrive.

Here are a couple of other blog posts about our customers using their tools for cabinet making and furniture making:

Woodworker Nick Buchholz’s ShopBot helps him explore new areas of design

Andy Pitts to other fine woodworkers: “Don’t be afraid of CNC!”

ShopBot Tools in large-scale manufacturing: Wood-Mode

Leave a Reply