Founded 20 years ago in the UK, Astor Bannerman is a company that designs and manufactures specialized furnishings — including baths, lavatories and office desks — for use by people with special needs and their caregivers. I spoke with Astor Bannerman’s Technical Director Peter Deverson about the unique challenges of their work, and how adding a full-size ShopBot Tool to their shop has enhanced their ability to serve the needs of disabled people.

Peter has a background as a mechanical engineer, and his business partner James Stuart-Smith holds an engineering degree as well as a degree in patent law. “From early on, we focused efforts on designing and building baths that raise and lower easily,” said Peter, “as we wanted to be able to meet the changing needs of a growing child, as well as to do everything possible to provide a comfortable and respectful setting.”

“We are very aware of how the equipment we manufacture affects the lives of the people that use it,” said Peter. “We have very high standards in both design and customer care, and due to its versatility, the ShopBot assists us in achieving our goals. It’s important to us that we achieve a beautiful looking product, a comfortable product, and one that exceeds standards for safety.” Peter explained that they put their new baths through a rigorous testing regimen of up to 100,000 cycles. “We punish the baths pretty harshly, opening and closing the moving parts, and raising and lowering the baths,” said Peter, “as we don’t want any patient to get hurt using our baths.”

One of many unique products is the company’s VANNA height-adjustable bath:

As noted on their site, “This bath gives the client and the care giver much greater freedom and control through day to day life. With its simple elegant design and convenient side door, the VANNA allows for easy access in and out of the bath. The height of the bath can easily be adjusted at the touch of a button and also allows for the powered door to be opened and closed for quick and easy transfers. The VANNA bath gives both clients and the care givers the control to do more at the touch of a button.”

To get the best sense of its capabilities, particularly how it moves to accommodate helping the client get in and out of the bath with minimal difficulty, watch this short video:

Peter explained the various ways that the ShopBot Tool was critical to their ability to bring this design to fruition:

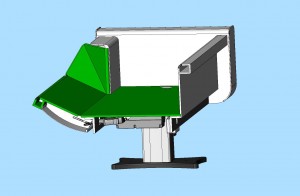

“This image shows how the base, door, door top roll, side wings and returns are all made from the same sheet of polypropelyne plastic by using fretting and controlled routing using a ball nosed tool – all of the material highlighted in green is the same piece of plastic. You can see that along with fretting, we use a 90° tool to produce 90° ‘corners’ in the material which allow us to fold the material through 90°. The two 90° folds allow us to locate the material into the back face of the door which helps during manufacture and produce a strengthening beam along the length of the door. This image also shows the door closing mechanism incorporating a slot to prevent damage to the bath if someone were to sit on the door before it was fully lowered.”

Peter emphasized that the precise hinge cuts that they achieve with the ShopBot Tool enable them to create a water-tight bath, with ‘soft corners’ rather than sharp edges that could become uncomfortable for the bather, and help ensure maintenance of the bath’s hygiene.

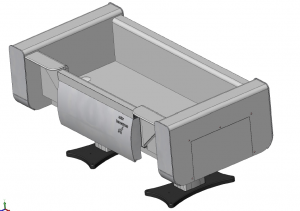

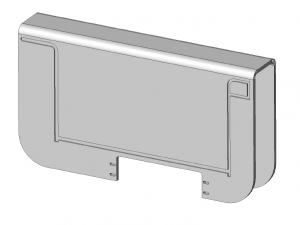

Peter said, “This diagram gives an overall impression of the bath and also gives a better impression of the engraved company name and logo on the front door. The engraving of our company logo is performed on the inside of the door so that the outer face of the door remains smooth. It’s illuminated from behind by a couple of green LED lights (which the customer can switch on or off as they wish – there’s nothing worse than a green light keeping you awake!).”

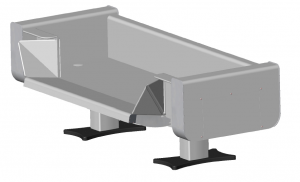

Peter explained that the “open door” image below indicates how the door opens and one can see the ball nosed routed paths that make up the hinges.

“The illustration shown below of the sectioned end box / fretting shows how we use fretting to make up the radii of the bath from a solid 12mm thick sheet of polypropylene (PP). There are a couple of reasons for this, the first is to help protect the client (the person in the bath) if they have a tendency for spasms or flailing about, the other is hygiene. By having radius edges we avoid overhangs and hidden corners where pathogens can hide,” explained Peter.

“This end box image (to the left) shows how by using the router, we create a path into which all of the components fit. This has two benefits: it allows a convenient reservoir for the adhesive we apply to all the joins and also helps with assembly as the components are held in position rather than requiring expensive jigs to hold it all in position. Once the adhesive has set we apply a plastic weld to all the joins; this is a belt and braces approach to bonding the joins and also produces a better aesthetic while also making it easier to clean and reducing hiding places for pathogens.”

Another example of Astor Bannerman’s use of the ShopBot tool in production of their designs is the Syncra:

“The Syncra Standard Modular bath is designed to offer comfortable and safe independent and assisted bathing,” said Peter. “The fully powered transfer seat and bath are operated at the touch of a button, allowing for quick, comfortable and easy bathing for all mobility levels.”

The seat can easily be detached from the bath by the means of the optional transfer frame enabling easy bedroom to bathroom transfers. The Syncra standard bath allows the care giver to perform any assisted bathing routine effectively and efficiently. Here’s video that helps paint the picture of its capabilities:

“We used the ShopBot router to produce the moulds for the seat back and base and also the mould for the long side panel,” explained Peter. “We did this by creating a 3D model in Solidworks, importing the model into Partworks 3D and producing a programme for our ShopBot. There was a little hand finishing of the moulds, but in essence the router was capable of producing what we needed in a sensible time frame.” (See picture below:)

“The challenge here was, we needed to react to the National Health Service’s requirements for a larger bath — there was a poor supply of these sizes, and frankly it was the ShopBot that allowed us to re-engineer one of our baths to a larger size in just two weeks -there’s no way we could have done that without the ShopBot,” said Peter.

“The picture above shows how the bath incorporates a few other items that we manufacture on the ShopBot,” said Peter. “I’ve removed the seat back so that you can see the hook assembly and the relevant components are highlighted in green. As part of the hook arrangement there are two guide blocks, one on either side, another at the base and a cover to the rear. None of them are very complex, but the ShopBot allows us to make small quantities in-house rather than investing in tooling and large batches of moulded components. That’s particularly useful to us as we effectively make bespoke products so it makes no sense to invest in large batches of components as they may remain on the shelf for years.”

Peter mentioned that when it came to deciding on a CNC tool, cost was part of the equation as Astor Bannerman is not a large company. “We did our web research, and we also came over to the US to visit ShopBot in North Carolina, get a tour and participate in their CNC training.” These activities impressed Peter and James such that they purchased their ShopBot PRSalpha back in 2005. “I also wanted to mention that tech support has been very helpful to us,” noted Peter. “We haven’t had to use their services much, but they’ve always been there for us when we needed them.”

Learn more about Astor Bannerman at their website. See more about ShopBot’s full size tools here.

Leave a Reply