My name is Lexus Pickett and I am with the Renaissance Academy Woodworkers. I am currently a senior who is interested in computer aided manufacturing.

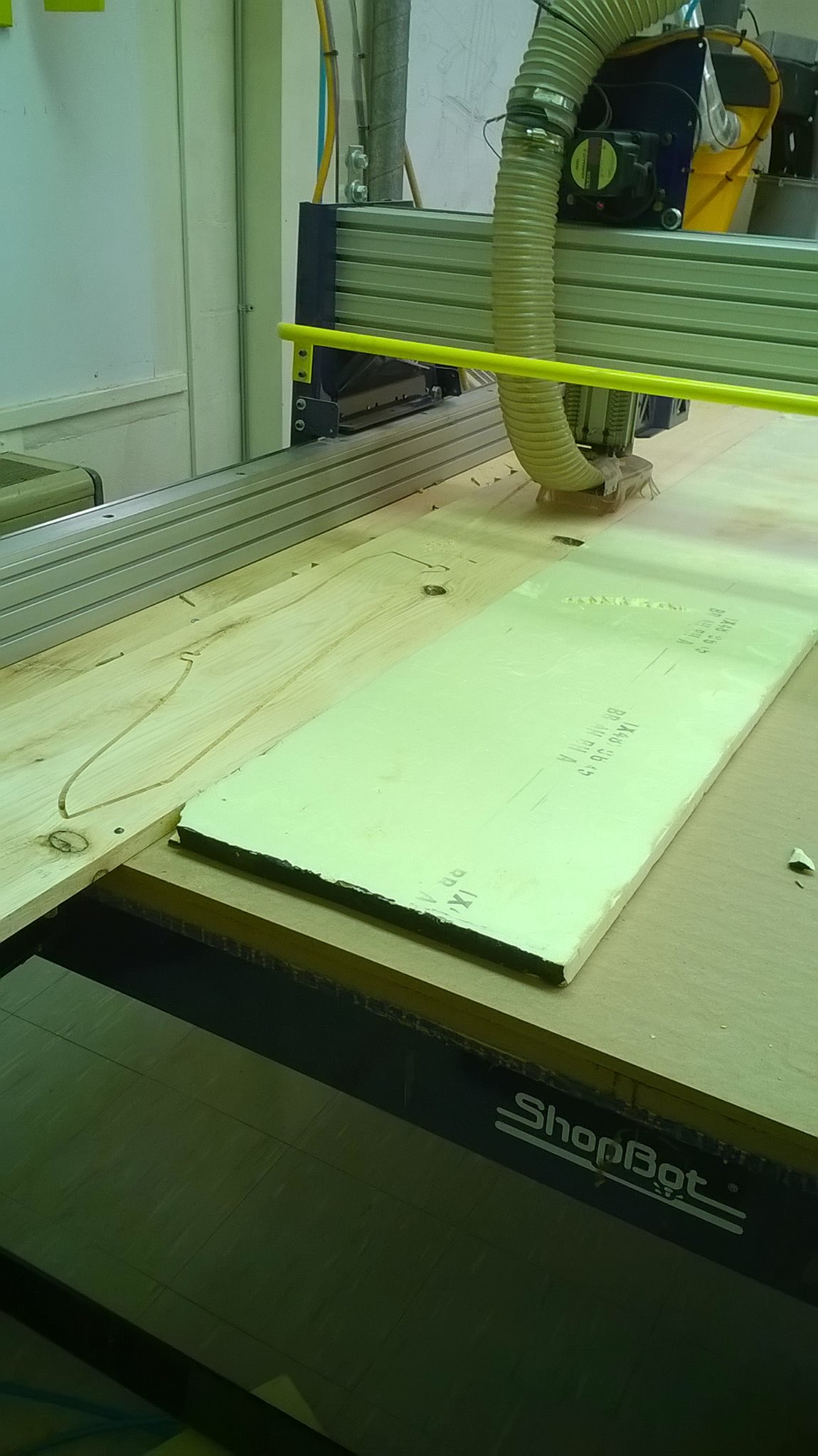

We are currently cutting out pieces for our Adirondack chairs on our CNC (ShopBot) machine. Our CNC machine has made manufacturing these chairs much easier. We used to use templates to trace the shape of a specific member of the chair, and then would proceed to cut out said piece on the band saw. The following step would be to sand the piece; it would then be ready to be a part of assembly. This method had many downsides, took quite a bit of time, and could use some improvement. With our CNC machine this process is sped up.

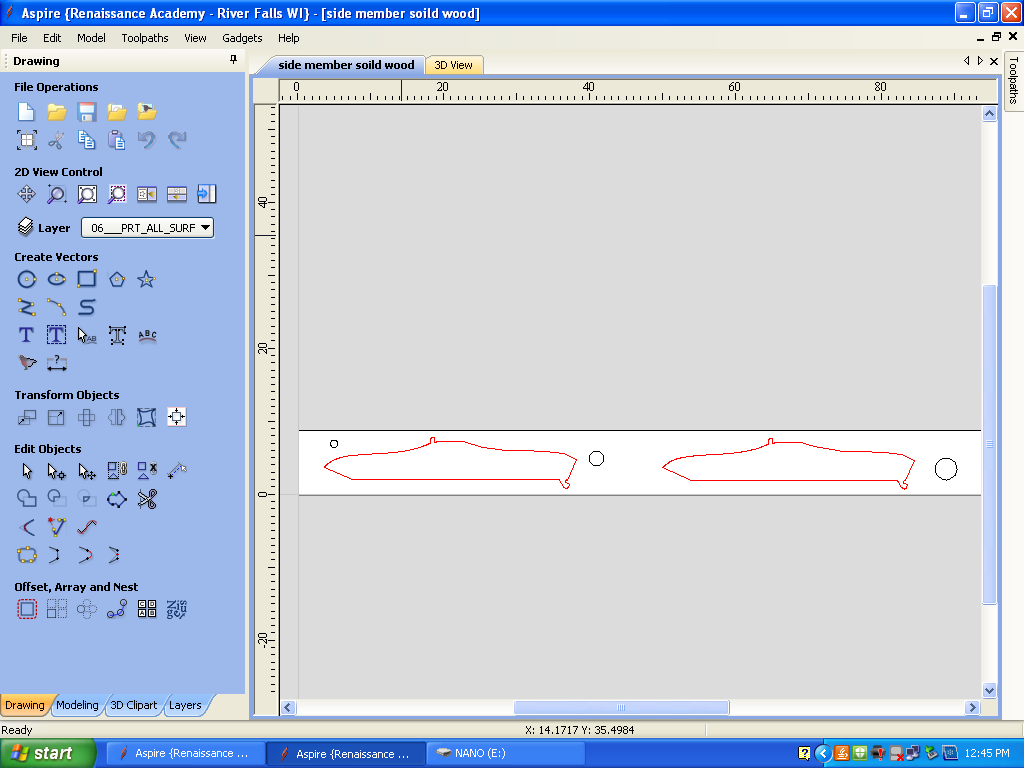

The procedure we use to produce the parts for the chairs is pretty simple. The CAD class created the chair in ProE and exported the pieces in dxf files. This is how the shape of the parts are imported into the Aspire program. We then choose a board of wood to cut the parts out of and screw it to the CNC table.

After putting the dimensions of the board into the Aspire program, we then have to put in any knots that are in the board onto the board in the program.

To do this we first measure the diameter of each knot and use the circle drawing tool to create the knot. Then we measure where the knot is and place it in the correct spot. From this point we place as many pieces onto the board as we can fit avoiding the knots. At that point the toolpath is run and we have perfect cut out parts for our chairs.

The part is now ready to be sanded and part of assembly!

Leave a Reply