A Case Study: Ryan Patterson’s MyHue.

The potential for individuals to create, design and manufacture products themselves continues to be realized every day all around the country. With the affordability of robust digital fabrication tools such as the ShopBot Desktop, running a micro-factory out of handy space is not a dream, but reality. We thought we’d share one example, Ryan Patterson’s MyHue product, and provide an overview of its production. Ryan is ShopBot’s Head of Production Support.

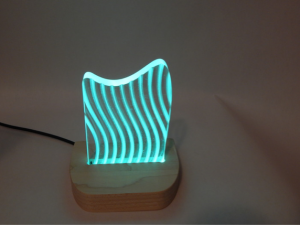

Ryan explained, “The MyHue is a unique visual notification system that displays colors when you receive a text, e-mail or other notification on your phone.”

“The idea for MyHue originated from my work environment,” Ryan said. “Our office is primarily one room with a large number of employees sharing the space. As the number of employees using smart phones increased, the number of audio notifications has grown tremendously. We all constantly hear everyone’s beeps, music, engines racing, and other notification sounds as the endless texts, emails, weather alerts, and alarms come in throughout the day.”

“I thought it would be much better to have a visual display on my desk and not need the audio. I knew my coworkers would be much happier as well. Using MyHue, each time I receive a notification, MyHue displays a color preselected for that particular notification. With my settings, blue means I have a text, red is a new e mail and white is a phone call.”

Here’s a video of MyHue in action:

“I realized MyHue would be great in many other environments,” continued Ryan. “My wife works in a very quiet office where the sound of an incoming text is a distraction to others. She also spends a lot of time with customers on the phone. She does not want customers to hear her cell phone notifications being heard in the background. MyHue sits on her desk and she instantly knows she has a notification without disturbing anyone. The same goes for a noisy environment. When I am in my wood working shop, I cannot hear an incoming text or call, but MyHue lets me know I have one.”

“I took the idea a step further and created multiple MyHues. This works great when I am at home. If my phone is in the bedroom, I will receive a notification when I am in the living room, kitchen or back patio – anywhere I have a MyHue.”

Steps in Prototyping and Production.

Producing a MyHue consists of three basic steps: cutting the acrylic lens, the wooden base which holds the lighting and lens, and cutting the electronic circuit board.

The MyHue is available in two sizes with several lens designs to select from, and allows for customization with up to 15 characters (you can add your company name, your name, initials, etc.)

Ryan uses the ShopBot Desktop to cut the profile of his lenses, as well as to engrave the designs into the acrylic. He created a vacuum hold-down fixture of HDPE (using the Desktop) to accommodate cutting the acrylic.

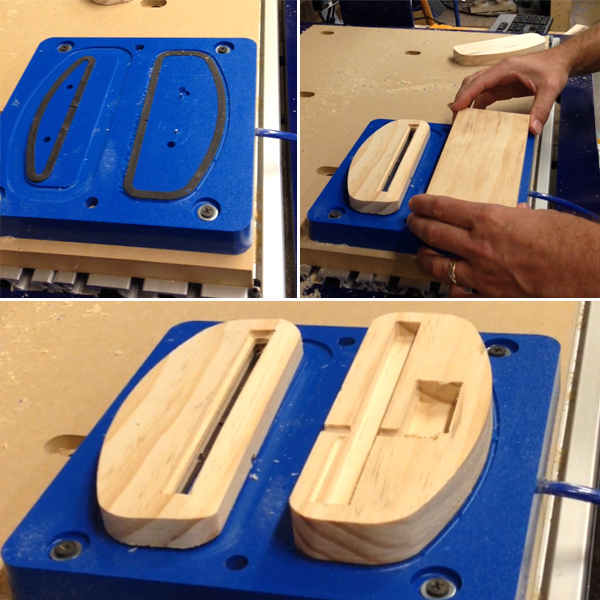

Cutting the wooden bases for MyHue is a two-sided machining job. To ensure the exact line-up of the cuts, Ryan created a vacuum fixture. “The first cut into the wood is to make a pocket for the electronics and also the overall profile of the base,” explained Ryan.

Then he flips over the piece of wood, to make the second cut of the profile contour and also the pocket which holds the acrylic lens.

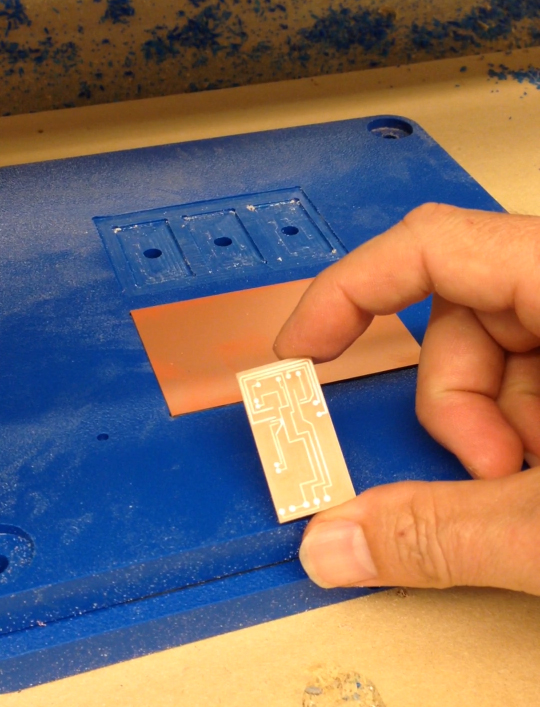

Finally the circuit board needs to be cut, and this is also a 2-sided machining job. To ensure exact placement of the copper pieces, Ryan created a fixture of HDPE with 2 pockets, to hold in place two circuit boards. The first pass with the ShopBot cuts the front side of one circuit board and the back side of the other; then you remove the copper pieces, flip them over and repeat the process.

“One of the challenges with such a small piece of copper is keeping the material exactly in place,” noted Ryan. “The trick was to create tabs around the material small enough to be able to snap out the pieces, yet also large enough to hold the copper down while working.”

Once the circuit boards are cut, he does the soldering and prepares the electronics, and then does the final assembly of the base and lens. Voila! MyHue — ready to ship.

Are you getting ready to prototype and/or produce a new product? ShopBot Tools offers production support services to help you configure the proper workflow for you. Just give us a call and ask for Ryan.