Professors at Florida State University in Tallahassee are helping to prepare their students for a multitude of career possibilities, by exposing them to the techniques of digital fabrication. They’re making use of digital fab from many angles, and it’s fascinating to learn about.

Windham Graves is a studio technician who heads up the Multi-Modal Additive Printer (MMAP) project at FSU’s Facility for Arts Research (FAR), part of Florida State University’s College of Visual Arts, Theatre & Dance. FAR incorporates both Small Craft Advisory Press (SCAP), which blends traditional and digital printmaking processes and promotes collaborations to create artists’ books, and formLab, which gives artists, designers and scientists access to a variety of tools they can use to create unique 3D objects and explore and visualize form in a tactile, multisensory way.

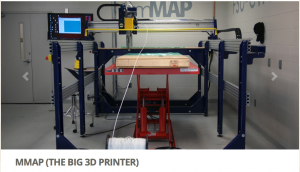

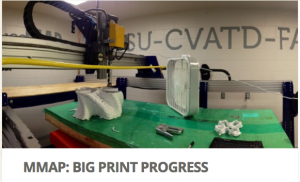

Graves says that the MMAP project is “to design, build and test a large-scale 3D printing system. Our goal is to create a robust, modular, multipurpose platform for use in material research, experimental form generation, and human-scale art making. Basically, it’s a Makerbot on steroids!”

The print envelope measures 8x6x4 feet, a volume of 192 cubic feet or nearly 5.5 cubic meters. The Multi Modal Additive Printer system consists of a X/Y gantry system with a descending Z-stage to facilitate the use of granular bed fill, deposition/extrusion processes, or a combination to allow a wide choice of material, method, and output options.

Graves and the FAR reached out to ShopBot Tools in Durham, NC, to help the FAR team build the MMAP. ShopBot’s Gordon Bergfors notes, “This was a custom tool. We provided custom legs to get the rails high and added standard parts (table sides, upper, lower and cross supports, gussets…) to complete it. It has an alpha control system and a normal gantry (X,Y&Z).” The MMAP project is progressing with the addition of customized software development and a computer controlled hydraulic build surface.

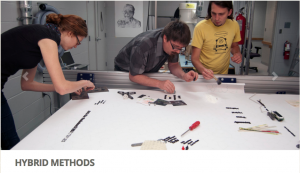

FAR staff also created Hybrid Methods, an experimental video, as an introduction to the facility for Florida State University’s Digitech 2012 event. Hybrid Methods uses a CNC Cartesian robot to create a complex camera motion path through a landscape of digital and physical objects and typography that illustrates FAR’s mission. FAR’s Windham Graves appears in this photo (on the right).

Marlo Ransdell, PhD, is Assistant Professor, Department of Interior Design and Creative Director, Studio D: Design and Fabrication Lab. She teaches the Department of Interior Design’s Graduate Furniture Class. Prof. Ransdell notes, “My students primarily come from a background in interior design or architecture, and in terms of their career goals, they are preparing to become commercial designers in areas such as hotel, office or healthcare design. Many intend to work in design education as well.”

Prof. Ransdell also noted, “While historically my students happen to be primarily female, we’ve seen that as word gets out that we are doing a lot of making and building things here, more males are getting interested in our department too!”

The Graduate Furniture class’ most recent project and accompanying gallery exhibit is entitled “Digital Fabrication – The Flat-Pack Furniture Project” at the William Johnston Building Gallery at Florida State. This exhibition presents furniture pieces from the Department of Interior Design’s Fall 2013 Graduate Furniture Design class which were designed and fabricated at Studio D and the Facility for Arts Research. The student challenge was to design two full-scale furniture pieces constructed from one 4’x8′ sheet of ¾” maple plywood in a 6-week time period using Rhino software. Each furniture piece was designed to be CNC manufactured and flat-pack shipped, have the ability to be constructed with little to no tools and hardware, and minimize material waste.

The students were encouraged to make their projects relate to an area of personal interest. For example, one student, interested in the healing arts, developed a meditation chair and side table. Another student made a study of Haitian orphanages and then designed furniture that can be used either as a desk or a chair, in order to best work within the limited size of classroom space in the orphanages.

Here are photos taken of the exhibit….

Prof. Ransdell says that “one of the goals of this project is to inform student designers with hands-on knowledge of the digital fabrication processes used today.”

“They will not necessarily become fabbers or makers themselves,” she says, “but they need to know current (and future) processes, and that includes learning how physical model-making and construction techniques help designers realize their ideas.” The students will typically begin by working in Rhino software and creating 1/6th-scale models of their work using a laser cutter. They will usually make up to six models at a size of about 8″ x 16″. When it’s time to go to full size, they will move to their new ShopBot tool, a 4′ x 4′ gantry CNC.

Ransdell notes that “working at full scale with the ShopBot really energizes the students. Taking their designs from 2D cuts to constructing the materials into their final 3D shapes is exciting — they learn hands-on about joinery — it really communicates principles of volumetric thinking.”

What are you up to in your educational program? We’d love to hear about it.

Leave a Reply