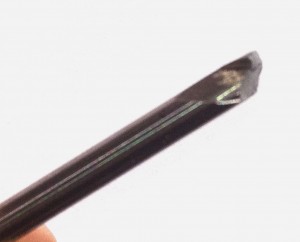

Sometimes things just don’t go like you planned in the shop. As I was working with a student on our latest project…which I hope to blog about soon…I ran our Ø 1/8″ carbide end mill into a hold-down screw, shattered the tool and ruined the work piece. This is why it’s important to keep your safety shields in place and to wear safety glasses when running your machines folks!

I’ve been experimenting with some of the different hold down techniques that TJ from ShopBot Tools presented in a webinar in July 2013 but when working with full sized panels in my Desktop, it just seems easiest to drive a few screws into different places to secure the panel to the spoil board. I guess that I’ve been pretty lucky with my screw placements up until now…

Since I expect to continue using screws to hold down full-sized panels in my ShopBot in the future, I was thinking about how I could avoid crashing my end mills on hard screws …especially on heavily nested panels. As I was vacuuming up little bits of broken end mill out of my machine, I realized that I could just have the ShopBot spot drill safe screw locations for me!

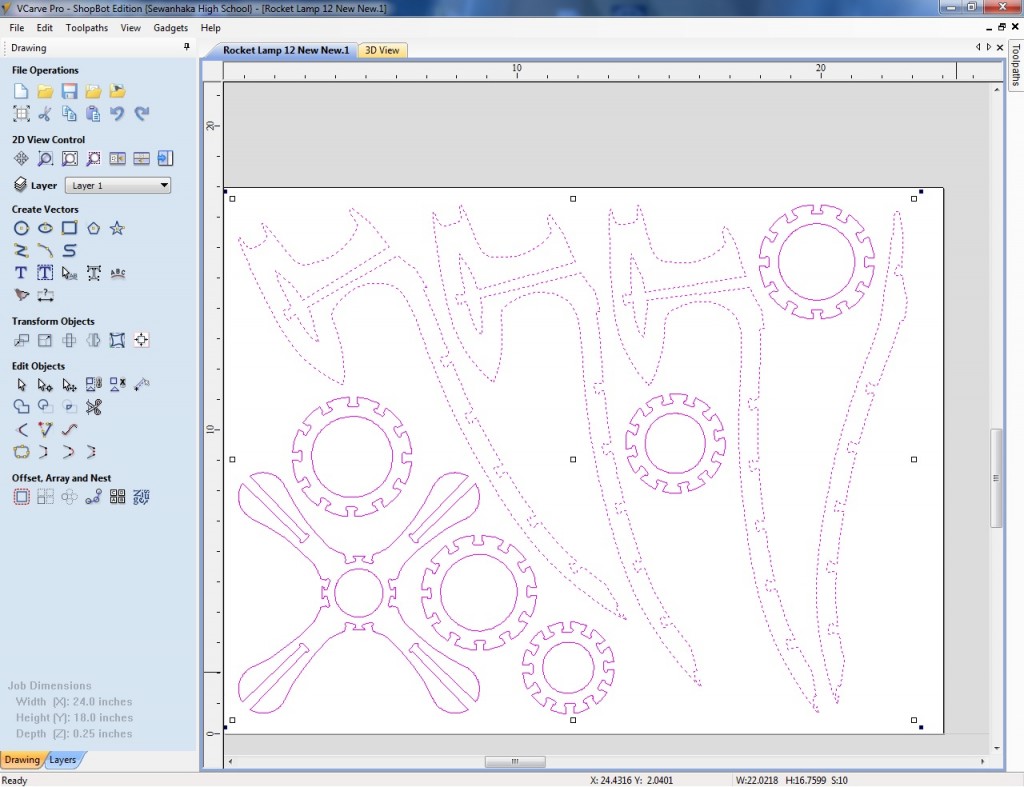

The panel my student and I were working on originally looked like this:

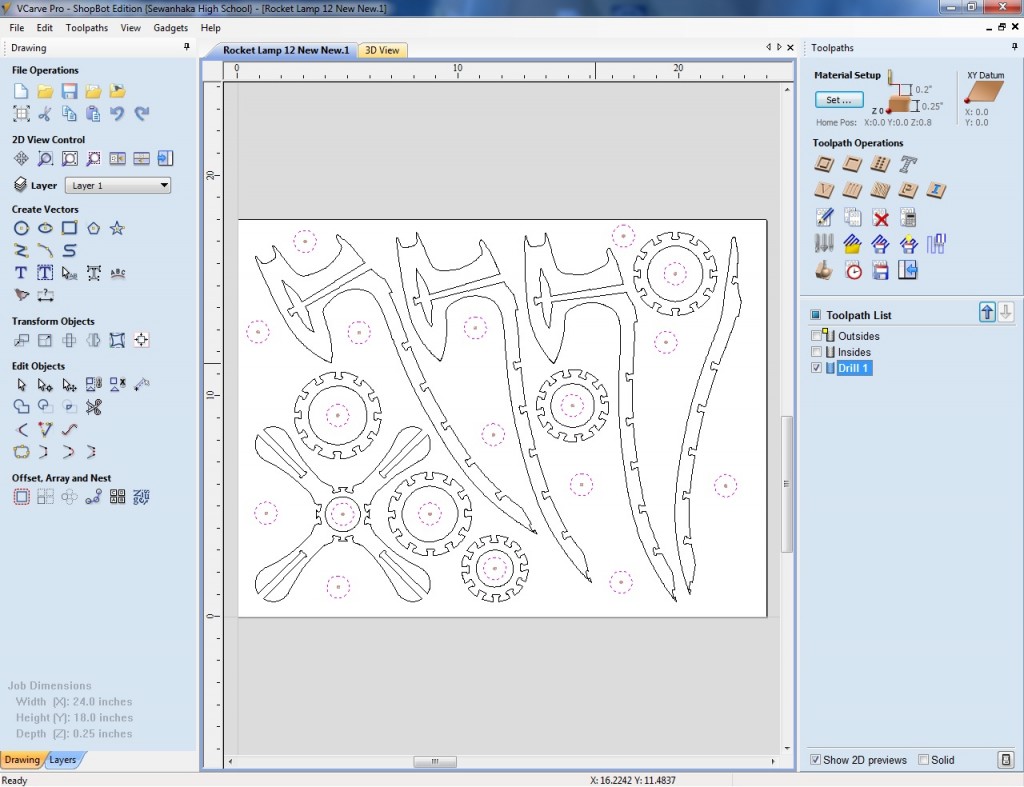

Adding in 1″ diameter circles to mark the centers of safe locations on the panel for screws gave me this:

I created a drilling toolpath using the centers of the circles I just added, put two screws into locations that I knew to be safe to temporarily hold the panel, and ran the drilling toolpath to mark locations for additional screws. Everything worked out great!

Here’s me putting the final few hold down screws into a new panel before milling out profiles.

So in summary, be careful out there! Always wear your safety equipment and pay attention to how you hold down your workpieces! Happy Shopbotting and please let me know if you have any better ideas for safely securing materials for cutting….I’d really appreciate it!

All the best,

Jack

Leave a Reply