Well, I finally took the plunge. A little over a year ago I reached the point where drilling and cutting full sheets of material was pretty routine, but having to manually draw, nest and toolpath the sheets full of parts was so time consuming – and occasionally error-prone – that it was becoming obvious that I was now the bottleneck of the whole operation. Something had to be done to streamline the process of getting files to the ShopBot. So I made software a priority at last year’s IWF woodworking machinery show. What I found was a variety of options ranging from a few hundred to a few tens of thousands of dollars. After looking closely at several of the more promising options I invested in CabinetVision software. Being one of the more expensive options it’s certainly not for everyone, especially since the ShopBot Link for e-Cabinets came out a few months later at a much lower cost. So instead of trying to sell you on any one software package I figure I’ll mention some of the features that are available and show you some of the benefits of using dedicated cabinetmaking software to keep the machine humming.

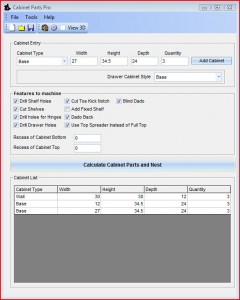

The Cabinet entry sheet in Cabinet Parts Pro.

Keep in mind there are dozens of software packages that are focused on creating cabinet parts, and I’m not an expert on any of them, although I’m getting pretty proficient with the one I chose. I’m only mentioning a few of the many products that are available by name, and I’m not endorsing any one over another. So if I fail to mention one that works for you (or one you sell), forgive me. I’m just recounting my personal experiences here, and you should take this (and anything else I say or write) as my personal opinion. Feel free to e-mail me, and if I’ve made any major omissions or errors, I’ll mention it in a future installment. A quick Google search for “cabinet making software” or something similar will get you a long list of options to investigate, if you are in the market.

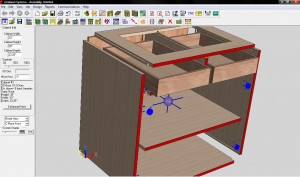

A view from e-Cabinet Systems, showing an assembly in Cabinet Editor view, compliments of Gary Campbell

There are several aspects of cabinetmaking software, and you may or may not need any or all of them, depending on your situation. The most basic versions allow you to enter cabinet sizes and generate nested sheet patterns and .sbp files. Cabinet Parts Pro and the entry level of CabinetVision fall into this category. You use a fill-in page (Cabinet Parts Pro) or go through an Assembly Wizard (CabinetVision) to tell the software what joinery options you use. For non-cabinetmakers who just want to make a set of cabinets for their own kitchen or bath, or for a shop that will just be cutting parts for other shops, this is a good way to get started and may be all you ever need. Some cabinetmakers use inexpensive rendering software to generate 3D renderings for client presentation, then enter cabinet sizes into Cabinet Parts Pro to get ShopBot files. For the budget-minded, this is a good way to go.

This rendering was created in KCDw by Erminio Marrese

Moving up in complexity and price, the software will allow you to create rooms filled with cabinets, and generate shop and/or client presentation drawings including plans, elevations and 3D renderings. E-Cabinet Systems, KCDw, CabnetWare, and the higher versions of CabinetVision (and many others) all provide this. With some of these packages nesting and machine output are included, with others you have to purchase an additional module or import the output into another software (such as PartWorks) to do the nesting and/or file generation. Some packages have pre-made libraries of cabinets that you can choose from to create a room, others allow customization of individual cabinets, such as adding dividers and shelves, and specifying whether each opening has doors, drawers, shelves, hanging rods (for closets), etc. The beauty of an all-inclusive package is that it is seamless from design to machining (sometimes called screen-to-machine), without having to output to another program to generate machine files. Parts are accounted for automatically, saving countless hours and freeing up time to work on the layout and aesthetics of the design instead of laboring over cutlists, nesting layouts and other tasks which are best suited to being automated.

The more feature-filled programs also keep track of pricing and bidding, and generate assembly drawings and reports, such as door and drawer lists for building or outsourcing doors and drawers, and hardware lists. Some do a better job than others of generating photo-realistic renderings, or again, require an additional module. For truly custom work, the more expensive software packages (CabinetVision, MicroVellum, 20-20, and several others) allow full customization of cabinets right down to the individual parts, such as changing the shape of a part (creating an arch or a notch) or adding machining (a wire access hole, for instance). The most advanced packages allow the creation of custom joinery and the associated machining operations, such as line-boring or dados, and the ability to apply those joinery operations automatically whenever certain conditions are met, that is, whenever specified parts touch each other in specified ways.

This rendering (left) helped sell the job. The client could see exactly what she was getting. The completed kitchen is shown at right.

As I mentioned, pricing varies widely. For a few hundred dollars you can be cutting parts with Cabinet Parts Pro (developed by Ryan Patterson, who now works for ShopBot), and use a free or low-cost architectural rendering program if you need renderings. E-Cabinets is a free package (for cabinetmakers) that handles the design and renderings as well as many of the other pricing, drawing, and report tasks mentioned above. It was developed for users of Thermwood CNC machines (and therefore has impressive tool control features such as slower machining for small parts). If you want to be able to output ShopBot files directly from e-Cabinets, you can buy the ShopBot Link for $1,295. Many ShopBotters have found this to be a great cost effective way to handle design and file generation. Many of the more expensive programs, like KCDw and CabinetVision, have tiered price points, and essentially let you choose which level of features you need now, with the ability to add features as needs and budget dictate. A few programs have rental or monthly payment options, allowing you to use the software as long as you pay the monthly rate, and avoid a large, one-time expense.

Once you have complete control over part sizes, shapes and textures, anything is possible.

It’s important to realize that with all but the simplest programs, there will be a significant time investment required to become fluent with all the options, settings, and techniques that will allow you to create those beautiful 3D renderings and the sheets full of accurately cut parts. The more powerful and flexible the program you go with, the longer it will take to get really good at it. There is no way around it (except maybe hiring an expert to run it for you), but there are a few ways to help streamline the process and reduce the inevitable frustration that results from seeing a screen full of icons and not knowing what 90% of them do, or knowing exactly what you want to do but not knowing how to tell the software how to do it. Reading the Help files is a good way to familiarize yourself

These renderings were made in CabinetVision for a friend’s new web site.

with how a software package works. It’s an obvious resource that some people overlook, and typically if you just start reading from the beginning you can get the basics quickly. I visited and re-visited the Help files within CabinetVision repeatedly over the first few months, and always learned something new that pertained to whatever I was working on at the time. Most better software makers offer training options of some sort; with e-Cabinets there is a series of training videos you can purchase and view at your leisure. CabinetVision offers regional classes, in-shop training by the day or one-on-one online training by the hour. Both also have well-utilized forums, similar to the Talk ShopBot Forum, where you can get answers from other users and even company technicians. Check to see what training options exist for whatever package you are considering, and then take advantage of them.

After using and learning my new software for over a year, I can say it was exactly what I needed to complete the picture of cutting out projects efficiently on the ShopBot. In addition, the ability to compose and view the project in 3D on the computer gives me huge benefits in construction and installation efficiencies as I can more easily visualize how all the parts and all the cabinets fit together before I cut the first part out. The 3D renderings are a big hit with my customers and have helped me look more professional and sell more jobs.

Leave a Reply