Sooner or later every CNC operator will come face to face with a challenging material hold-down problem that cannot be solved using conventional methods. Clamps get in the way, tabs/bridges require post-finishing of the part, screws don’t hold the part down in the center and vacuum is sometimes not strong enough for small parts without specialized gasketing.

One very versatile and effective method is to use carpet tape. There are a few different configurations of carpet tape out there. You want the stuff that has coarse fiberglass mesh in it that is labeled ‘Indoor/Outdoor’. There is adhesive on both sides of the mesh and the adhesive is protected by a paper coating until you are ready to remove it and secure your material. When you are ready to secure your material to the spoilboard, clean both the spoilboard and material to be secured. Apply carpet tape to the spoilboard if you are cutting a full sheet, or to the part for smaller material. Then, run a laminate roller down the tape to get good adhesion. Remove the paper being careful not to kick up any dust or debris. If you are handling a full 4X8 sheet, have someone help you place the sheet squarely on the spoilboard. If you don’t place it carefully and move it, the tape may get displaced creating a lump of tape under the material. After you have placed your material on the adhesive, press down or walk on the material to create a good bond. You are now ready to cut with no tabs, screws or clamps.

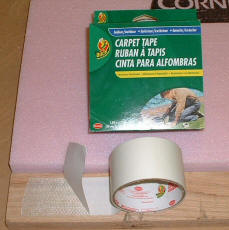

Carpet Tape

Depending on what you are cutting, you will want to use discretion when deciding just how much tape is needed to hold a part down. Not enough will cause a part to move when being cut and too much…well, let’s just say that you will have a really tough time removing it from the spoilboard! Experiment a little to find out what is best for your application. In some cases, the tape will leave a residue on your finished parts. You can remove it with either denatured alcohol or acetone. Always test a piece of scrap before using solvent on your finished pieces to determine if it is compatible! Acetone is not compatible with most plastics and will either de-gloss the surface (e.g. Sintra or Komatex) or melt the surface (e.g. acrylics & others). In most cases denatured alcohol will not harm your parts, but it takes a bit more rubbing to remove it from the part compared to acetone. Using denatured in a spray bottle & keeping the part wet while rubbing does the trick.

One thing that is nice about carpet tape is that it is available pretty much everywhere. I usually buy the Indoor/Outdoor or High-Traffic labeled Duck brand at Home Depot or Lowes. It comes in a few different widths and lengths. I buy the 2.5” X 75’ rolls for about $8. When I don’t feel like going all the way to Lowes or Depot, I go to my local Ace Hardware. They also sell the Indoor/Outdoor Ace-brand version in 42’ lengths. They sell a 1.5” and 3” version. Get the 1.5” version as the 3”, for some unknown reason, tends to not release from the protective paper. You may also want to experiment with upholstery tape, but it lacks the fiberglass mesh that helps you to pull the tape off in one shot.

For those who have the ShopBot digitizing probe, you will find carpet tape an excellent solution for holding part securely to the spoilboard for digitizing. This allows you to hold down parts that cannot be screwed down, clamped or damaged! This method is applicable to both 2D and 3D digitizing. Give it a try, I’m sure that you will find it a great addition to your current hold-down techniques!